Patent Report: Cooling system boosts blown film lines

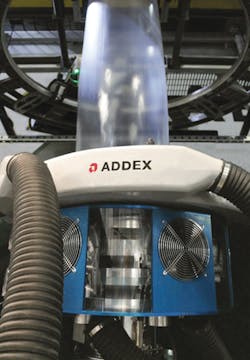

Addex Inc., Newark, N.J., has applied for a patent for what it describes as a unique cooling technology that increases output 40-60 percent for blown film extrusion lines.

"We've developed a major enhancement that takes earlier technology to a higher level and sets a new bar for throughput," said Addex President Bob Cree.

The design comprises a series of cooling rings arranged in a stackable configuration. Each ring directs divergent airflow along the bubble, both upward and downward from each stacked cooling element, providing peak cooling efficiency, according to Addex. Spacer pipes provide air to each cooling element.

An enclosure surrounds the stack, creating a stable, controllable, ambient pressure. Variable-speed, low-pressure fans establish the pressure differential between the inside and outside of the bubble.

Patent application has not yet been published.

In other patent news:

Molded containers. Kortec Inc., Rowley, Mass., invented a method that it says improves the gas permeability of containers used for food, medicine or other materials. Paul Swenson, the inventor, said that the new approach results in barrier coverage extending from 95 to 100 percent of the entire surface area. Four multilayer containers can be molded at once. Milacron LLC, Cincinnati, acquired Kortec in 2014.

Patent application 20160250789; published Sept. 1

Pipe inspection. Inventor Carl Raymond Douglass III, of Spicer, Minn., has applied for a patent for an inline system that uses automated laser technology for scanning and recording defects in the surface of the smooth inner wall of dual-wall, corrugated plastic pipe. A conical laser pattern passes through the dual wall to complete a 360-degree scan. The application claims the system has particular benefits for the production of coilable, dual-wall corrugated plastic pipe when the plastic being processed has undergone an alteration, such as the introduction of an additive.

Patent application 20160221244; published Aug. 4

Injection control. Synventive Molding Solutions, Peabody, Mass., says it has developed an improved system to adjust the positioning of one or more valve pins during an injection cycle. In the approach, a pressure sensor generates a signal based on barrel or manifold melt pressure. A controller receives and uses the signal to actuate valve pins to reduce melt velocity to maintain constant pressure. The patent application claims the invention would overcome limitations in current approaches. "This patent would complement our existing activeGate control technologies," said Desmond Crowley, marketing communications manager at Synventive.

Patent application 20160229102; published Aug. 11

Resin transfer molding. The push for carbon-fiber-reinforced plastic parts in automotive manufacturing applications is triggering efforts to improve the cost-effectiveness of the process. First Composites GmbH, Niederbreitbach, Germany, has invented a system it says can detect when a mold cavity is completely filled with injection material, minimizing waste. A measuring unit detects resin escaping from the closed mold. The escape outlet is closed when material is detected.

Patent 9,393,743; issued July 19

Cooling device.

Battenfeld-Cincinnati Germany Gmbh, Bad Oeynhausen, Germany, received a patent for a method of calibrating and cooling plastic sheet or film that it says overcomes some of the deficiencies of widely used systems. At every operating point of the extrusion installation, the cooling of the film largely corresponds to the theoretical thermal conductivity of the film, according to the patent.

Patent number 9,427,906; issued Aug. 30

Honeycomb extrusion. Corning Inc., Corning, N.Y., has invented an approach to extrude a plastic/ceramic honeycomb, providing correction in bowing of the extruded honeycomb structure. The system uses a deflector device that has a bow plate mounted to the base plate. According to the patent, the deflector device positioned upstream of the extrusion die imparts a degree of bow reduction. The honeycombs are used in catalytic converters.

Patent 9,393,716; issued July 19

Patents and patent applications can be viewed at www.uspto.govHave you applied for or received a patent? Contact [email protected]