Special Report: Laser marking and engraving following shifts in technology

The technology for laser marking and engraving is a growth area for plastics decorating, which can be attributed to changes in economics, features and software, according to several companies that make and sell the equipment. Energy efficiency and ease of integration are common goals in the engineering and design of this equipment.

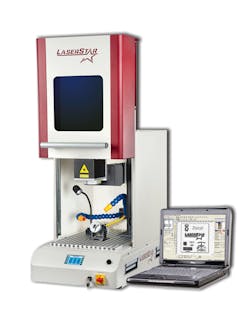

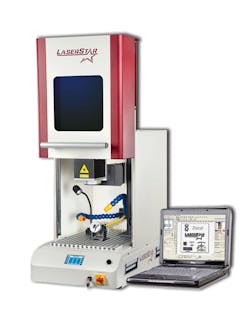

LASERSTAR TECHNOLOGIES CORP.

LaserStar Technologies Corp., Riverside, R.I., has developed its products to be compatible with technology shifts in plastics and their additives, officials say. The company performs hundreds of applications per year for its customers. It says the percentage of those that are related to plastics has increased dramatically in recent years.

"Our hardware and software has also paralleled these changes by giving our customers access through internal designs and software features to all of the newest capabilities of fiber and pulsed CO2 lasers," says Greg Anderson, VP of operations and engineering with the company's Fiber Laser Engine division.

Changes in the technology have occurred in three areas, officials say. They are the laser technology itself, the software and hardware features that use those advances and supporting technologies in plastics and inks.

Anderson cited some trends in laser marking:

• Low-cost fiber laser technology has done more than bring costs down and increase companies' returns on investments; it has provided unique abilities that affect processes that can be used to successfully mark on plastics.

• Consistent pulse-to-pulse stability, higher energy densities and lower frequencies without the higher peak powers of traditional lasers have led to new processes that are very effective at creating contrasting marks on plastic.

• The advances in the CO2 laser with newer wavelengths and real enhanced peak power pulsing coupled with higher powers in a maintenance-free, no-chiller-required package, have made the traditional plastics laser even more attractive to the industry.

Perhaps the most important technology changes have not even been in the laser itself, he says.

"Our engineers have, over the years, worked directly with companies involved in developing chemical additives for plastics that guarantee quality and contrast," Anderson says.

This area of plastics decorating can be tricky, officials agree, and it isn't just a simple machinery or equipment tweak that has made this a viable choice for more plastics substrates.

"Laser marking and plastics has always been a less forgiving process than marking on metals," says Anderson. "The consistency in providing contrast is always difficult and can change from one color of the same plastic to another."

Through its R&D efforts, LaserStar says it has gained the knowledge to provide that consistency through use of appropriate laser wavelengths, and unique software and optic applications. With these advances, the plastics industry can now be pulled into the forefront of laser-marking technology, so that it can reap the benefits of noncontact, nonadditive, permanent marking and identification.

"Whether it is bar codes, serial numbers or company logos, plastics can now attain quality results and production speeds," Anderson says.

TRUMPF INC

At Trumpf Inc., Farmington, Conn., officials will introduce a new ultraviolet laser to the North American market in the spring. Thomas Burdel, national sales manager, TruMark, reports that Trumpf will introduce its TruMark 3330 into North America after it was exhibited at a trade show in Munich in the summer.

The laser is designed to integrate very easily into an automated system and it is air-cooled, so it does not need a chiller.

"With plastics, we have a variety of lasers so we can actually find the best solution," he says. "We have lasers in different wavelengths, for example, a UV laser built for rugged applications like automation."

Trumpf also has worked in a marketing partnership with injection molding machinery maker Arburg Inc., Lossburg, Germany. Trumpf recently partnered with Arburg to place a TruMark 1110, a compact and cost-efficient marking laser, on Arburg equipment.

"So basically the part was molded, and before it came down the line, it was marked," says Burdel.

ALLIANCE LASER SALES INC.

Alliance Laser Sales Inc., Wauconda, Ill., recently introduced its NGRV51 Ytterbium Fiber Laser Engraver for tool makers, says sales representative Tom Stapleton. The equipment is ideal for a wide range of laser marking and engraving applications that require a permanent mark. It has a 100 percent solid-state design, which translates to lower electrical consumption. The design makes the laser up to 15 times more efficient than older, lamp-pumped systems. With the design, the equipment also requires less maintenance and has no lamps, mirrors or other consumables to replace. The laser is cooled by air and does not need an external water-cooling system. Also, it is more efficient due to state-of-the-art technology that allows for a beam quality that surpasses the beam quality of conventional lamp and diode-pumped laser engravers.

SCANLAB AG

ScanLab AG, Puchheim, Germany, says that lasers can help to fulfill industry requirements for permanent marking. As an example, the plastics industry has a growing need for individualized labeling of components using data such as serial numbers, dates or tracking numbers that are generated via an automated production process.

The company in 2015 released the basiCube scan head specifically for the plastics industry. The cost-effective basiCube can mark 800 characters per second, company spokeswoman Eva Jubitz says. The durable, waterproof markings resist smudges, solvents and abrasions. No molds or stencils are required, providing even greater design flexibility. The product was developed and is made in Germany.

ScanLab is seeing lasers used in high-volume production in which items have to be marked individually, as well as in operations that require batch control. Specific products that are decorated with lasers include dashboards and keyboards. The technology also is being used "on the fly" to mark products in motion, for example, as tubing passes out of an extruder.

Jubitz says the importance of quality assurance is rising, especially in applications like pill bottle marking. ScanLab has a product called ScanAlign, which calibrates the entire laser system and assures accuracy in the final product. It is based on algorithms that allow it to calibrate the laser processing system and ensure the correct positioning of the image. This is equipped with a camera, illumination capabilities, a calibration plate and a software package.

ScanLab has been getting more traction in the U.S. market for its products. The company recently expanded its efforts by naming Amanda Dobbins as director of new business development for the U.S.

Angie DeRosa, managing editor

Contact:

Alliance Laser Sales, 847-487-1945, www.alliancelasersales.com

LaserStar Technologies Corp., 401-438-1500, www.laserstar.net

ScanLab AG, 49-89-800-746-0, www.scanlab.de

Trumpf Inc., 860-255-6000, www.us.trumpf.com