Die design software improves algorithm

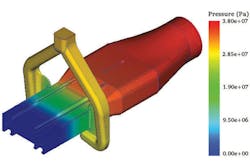

PolyXtrue Plastic Flow has released a new version of its extrusion die design software, which is used to examine the uniformity of velocity distribution at the die exit. The software also predicts the layer structure in coextrusion products, as well as the change in shape of the profile after it comes out of the die.What's new? The combined analysis of the flow inside the die and the heat conduction in the metal plates. The new version of PolyXtrue also can simulate polymer slip on the die walls for coextrusion. An improved algorithm reduces the time needed for flow simulation.

Benefits By refining a die before it is machined, the number of physical fine-tunings that are required can be cut by more than 50 percent, greatly reducing costs and speeding up production.

Plastic Flow LLC, Hancock, Mich., 906-483-0691, www.plasticflow.com