NPE: Hot-runner systems' versatility on display at NPE

Variety and versatility were key themes of hot-runner systems introduced at NPE. Suppliers introduced hybrid, changeable and turnkey configurations for molding large automotive parts and precision medical parts. They also unveiled new designs for molding prototypes. Space savings, energy efficiency and higher performance are reasons to give these systems a closer look.

ELEVATING PROTOTYPING

Ewikon Molding Technologies Inc., Rockford, Ill., debuted HPS III-FleX, an adjustable hot-runner system that can be reconfigured for use with different molds. The system can be used with two-cavity molds for small series or prototype production, which typically has used cold-runner technology.

System adjustability is created through the hot runners' design. A linear main manifold is combined with two lateral manifold arms of the same length. Special pivot-joint technology is used at the connecting positions to the main manifold, which allows the lateral manifold arms to be positioned within a defined angular range.

Depending on the angle between the main manifold and the lateral manifolds, the nozzle positions and the pitch distance (distance between cavities) are adjustable. HPS III-FleX can be used in a different mold with a different pitch distance by dismantling the hot-runner system from one mold and assembling it in the other mold, Ewikon says.

The use of standard nozzles allows for a full range of gating options, including direct-tip gating, screw-on gate bushings or valve gating. Valve gating uses a pneumatic valve-pin drive that is fixed on the manifold and is easy to integrate into the system. The main manifold and lateral manifold are stock components. HPS III-FleX is offered with flow-channel diameters of 6mm and 9mm.

NEW ENTRIES DRIVE

AUTOMOTIVE APPLICATIONS

The Fusion G2 hot-runner series for automotive and large-part molding applications from Mold-Masters Ltd., Georgetown, Ontario, a division of Milacron LLC, features nozzle, valve-pin and gate-seal developments. Fusion G2 is a drop-in system with a single point of connection to the injection press, which eases installation while promoting faster startup, operation and maintenance. Four models are offered – F4000, F5000, F6000 and F7000 – handling shot weights ranging from 15 to 3,500 grams.

Fusion G2 features include field-replaceable manifold and nozzle heaters; screw-in, slim-profile nozzles and multiple heater zones per nozzle for an optimized thermal profile; a valve-disk design that enhances the hot runner's ability to execute a color change; and an integrated, leak-proof design. It is completely pre-assembled and pre-wired.

Nozzle lengths have been extended for series flexibility. Compound nozzles are used to avoid interference with cavity cooling lines and can be positioned in very tight areas. Heated flange nozzles are available in addition to the standard screw-in nozzles that are threaded directly to the manifold. Nozzle lengths of the Fusion F7000 system range from 80mm to 700mm.

The system is available with a new valve-pin speed control, featuring a position sensor for pin movement. Valve-position monitoring helps to improve part surface finish at the gate area. Additional gate seals (in hot valve, hot sprue and F-type) are now also offered for the entire Fusion G2 product line. Mold-Masters offers new brazed-heater and pressed-in heater designs and heater plates as options.

Mold-Masters' Vision series hot-runner line, created for molding automotive lenses and housings and curved white goods, improves the flow through the manifold and nozzle, which yields parts with a better finish.

The system is composed of a specially engineered, one-piece, angled manifold made with stainless steel, and is pre-assembled and pre-wired. Vision features include simplified mold-plate machining and the ability to quickly and easily take apart the actuator by releasing the valve pin and field-replaceable components, including the heaters.

Users can select Vision Deci, which features nozzle lengths from 35mm to 215mm and handles shot sizes from 50 grams to 500 grams, while Vision Hecto has nozzle lengths from 50mm to 450mm and shot sizes from 500 grams to 3,500 grams.

Husky Injection Molding Systems Ltd., Bolton, Ontario, now offers its Unify series of pre-wired and pre-assembled manifold systems for automotive applications. It expanded the applicability of the systems from medical and packaging applications, says Dave Morton, VP Americas for hot runners and controllers.

The design provides one-step installation of the hot-runner manifold into the mold without the need to pre-heat the system, which reduces installation time by up to 70 percent and prevents the possibility of nozzle-tip damage. Unify can be configured from a choice of hydraulic or pneumatic valve-gate actuation styles or a variety of thermal gate nozzles. Electrical, water and hydraulic or air lines are mounted to a custom rigid frame that matches the mold layout, says Husky.

The nozzles are designed to self-align to the gates during installation. The Unify system features Husky's UltraSeal leak-proof technology, which allows the nozzles to slide relative to the manifold during installation.

Husky offers Unify for its Ultra 1000 hydraulic valve gate nozzles and will make it available for its Ultra 1000 pneumatic valve gate and Ultra 750 series, as well as for thermal gate (hot-tip) designs.

MANIFOLDS FOR MEDICAL APPLICATIONS

Mold-Masters introduced the Summit series of hot runners designed for molding shear-sensitive and temperature-sensitive materials used in medical applications, including PC, polyoxymethylene and polybutylene terephthalate. Several features and capabilities make this configuration a premium hot-runner system.

The Summit hot-runner system is made from stainless steel for enhanced chemical resistance. For tighter temperature control, the system provides one-fourth of the thermal variation from set point compared to that typically seen in a nozzle with a heater band. Highly conductive materials incorporated into the Summit nozzles also deliver an added level of thermal control, holding temperature variation to plus or minus 5 percent, according to Milacron.

The series offers new valve-gating methods using servo-controlled actuators to control the valve pin for high-precision molding. The valve pins feature coated front ends that enhance durability. The valves are individually operated, allowing users to adjust each valve's stroke or speed.

Summit also incorporates Mold-Masters' EcoDisk flush-mount pressure disks, which improve the energy efficiency of the hot-runner system by enhancing the seal between the valve component and the hot-runner manifold.

HYBRID DESIGN A HIGHLIGHT

Osco Inc., Rochester Hills, Mich., upgraded its hybrid multiple gate nozzle (MGN) hot-runner system for unique molding applications. The system incorporates Osco's standard MGN body, which is used for the manifold design, and its CVT-20 series of externally heated nozzles for the drops, says Bruce Gilgallon, technical sales.

The hybrid MGN offers design flexibility for applications with close center-to-center gate requirements coupled with longer nozzle lengths. The previous design used internally heated nozzles. The upgraded design yields better control of the melt at the gate, Osco says.

The CVT Series 20 nozzles are standard and are offered with four standard tip styles with numerous tip/gate diameters and four nozzle lengths. Other features include temperature control at the gate and heaters that are replaceable.

Osco also rolled out a smaller version of its MGN. The Mini MGN is suited to multiple gating of small molds and is compact compared to an "H" pattern hot-runner system. It can fit into a smaller mold base and smaller press. Material residence time is kept to a minimum, yet the system yields balanced fill rates.

The Mini MGN can process commodity- or engineering-grade materials in single-part applications that require multiple gates for concentricity, or can be used in a single gate serving multiple cavities. As many as 12 gate probes per nozzle can be used. Temperature control at the gate helps ensure balanced flow. Two probe styles are offered: one for use with unfilled materials and one for use with glass-filled polymers.

Osco also developed the valve-gate sequencer (VGS) control unit, which can hold as many as 20 different mold settings. The system can be used with pneumatically or hydraulically driven valve gates, or both, if desired. Valve-gate switching can be based on a linear position, cavity-pressure signal or time. Users can select the voltage at which to operate the unit.

An on-demand pump controls the power source to the valve gate and can eliminate the need for water lines to cool the pump. The VGS comes standard with a black-and-white touch screen (color is an option) with a control unit that is connected to a 20-foot cord and can be detached from the body of the unit. The system uses open-architecture software to facilitate upgrades. Molders interested in the technology can rent the VGS and try it before they buy it, says Osco.

TOTALLY TURNKEY

Yudo Inc., Livonia, Mich., is offering a complete system that brings together many of its technologies into a single system for injection molding. Yudo's Consilience Technology can supply hot-halves, hot-runner systems, temperature controllers, heating and cooling systems, auto-feeding systems, take-out robots and factory automation (such as gate cutting and in-mold labeling). It provides every device needed to mold the part, except the injection press, says VP Ken Salemi.

Consilience Technology systems can be designed for automotive, electronics, micro-engineering, packaging and PET preform applications. In addition, Yudo is planning to open a technical center in Canada, to be called YudoPro, that will have several sizes of injection molding machinery installed and will be used for customer trials and product system testing, says Salemi.

MINI IS MAJOR

Incoe Corp., Troy, Mich., introduced its HEM hydraulic valve gate cylinders to the North American market at the show. The compact hydraulic cylinders are suited for back-molding of large, natural-fiber mats used in automotive applications, such as door trim.

Features include enhanced thermal separation of distributors and cylinders, which prevents the hydraulic oil from reaching critically high temperatures during operation. The higher thermal separation also protects moving parts and seals. The upgraded design eliminates the need to cool the components when production work is complete.

With their smaller dimensions, the miniature hydraulics create space for supply lines. Outlets for the cooling lines can be arranged in four directions. HEM is available in a range of possible gating points.

CONTROL AT THE GATE

HRS USA Inc., Greenville, S.C., introduced its Flexflow servo-driven valve-gate technology to the U.S. at NPE. The servo-driven system, which independently controls each valve pin in the system by precisely adjusting position, acceleration, velocity and stroke, is accurate to 0.01mm. The valve pin controller is available in configurations that control four, six, eight, 10, 12, 14 or 16 zones.

It is suited to the molding of large parts such as automotive bumpers, grilles, door panels, instrument panels and center consoles. Flexflow can be used on plate, on manifold or in a lateral configuration.

The accurate control of pressure and flow rates by Flexflow cuts clamping force requirements by as much as 20 percent while reducing the possibility of tool bending, making it useful for low-stress molding. Part weight reduction of up to 5 percent is possible while the parts can be molded with a Class A surface. The valve controller helps to reduce part warpage as it optimizes flow balancing.

The system is compact and requires no pipes or connections for water or oil. Instead, each servo valve has its own control for higher process repeatability with the ability for optimal flow balancing in a dry, clean, oil-free environment. The valve-pin control and pressure and flow-rate control during part filling reduces the holding-phase peak pressure while yielding pressure distribution that is more uniform, says William Taylor, key account manager.

STACK TOOLS TARGETED

Mold Hotrunner Solutions Inc., Georgetown, Ontario, updated its pneumatically driven Rheo-Pro internal valve gate (iVG) to better operate in low- or high-cavitation hot-runner systems, including single-face molds, stack molds and multi-material injection molds.

The compact, pneumatically driven, patented valve gate allows a molder to produce parts on smaller machines using lower clamp tonnages. Users can build single-face or stack molds with a tip-to-tip length of 285mm and a pitch, or gate-to-gate distance, of 63.5mm, says Jörg Schmidt, director of business development.

The design allows the system to operate without elastomeric seals, lubricants or cylinder cooling. And unlike electric actuators, iVG can operate at temperatures of up to 750 degrees Fahrenheit.

Stack molds and tandem molds can benefit from use of the Rheo-Pro iVG, which can be used inside a stack mold as a way to transfer melt from a stationary tool to the first parting line. Rheo-Pro iVG can be used with lower stack mold height, requiring a smaller press and reducing operating costs.

The Rheo-Pro iVG can be serviced from the front of the mold parting line – including the nozzle, valve actuator and valve pins – by stripping the cavity plate onto the core side while the entire mold remains inside the machine. The valve gates are designed for durability and eliminate the need for components prone to wear such as O-rings, hoses, tubes, belts, motors or cooling elements.

MHS also showed its Rheo-Pro Black Box line of pneumatic servo-actuators, suited for use in clean rooms as a lower-cost alternative to an electric valve gate in a similar application. The actuator's switch can turn the system on or off within milliseconds, which ensures consistent part filling. It is ideal for cascade injection and sequential valve gating.

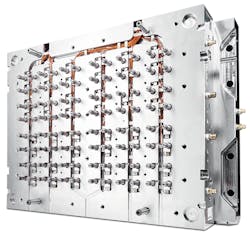

In addition, MHS showed its quick-start manifold systems. Available in two-, four-, eight- and 16-drop systems with four tip styles, they work with Rheo-Pro custom-engineered hot runners. Multiple standard system combinations are available based on a range of common mold layouts.

Mikell Knights, senior correspondent

Contact:

Ewikon Molding Technologies Inc., 815-874-7270, www.ewikonusa.comHRS USA Inc., 864-627-5373, www.hrsflow.comHusky Injection Molding Systems Ltd., 905-951-5000, www.husky.coIncoe Corp., 248-616-0220, www.incoe.comMold Hotrunner Solutions Inc., 905-873-1954, www.mhs-hotrunners.comMold-Masters Ltd., 905-877-0185, www.moldmasters.comOsco Inc., 248-852-7310, www.oscosystems.comYudo Inc., 734-744-8120, www.yudo.com