Software cuts tooling times

By Karen Hanna

Robots get most of the attention, but automation comes in many forms.

For Janesville, Wis., thermoformer Prent Corp., software tools to design both tooling and machines have saved labor and time. For more than 15 years, the company has used CAMWorks and SolidWorks, available through HCL Technologies Ltd., Noida, India.

Mike Courtney, a CNC programmer for Prent, cited as essential the ability of HCL Technologies’ software to automate the programming and re-iteration process. Prent, which makes packaging for medical devices, electronics and consumer goods, uses CAMWorks “to produce our parts that attach our molds and plugs to the thermoformers — the mounting tooling, which have many identical features in many different sizes.”

“Most of our tooling has all the same features on it, but we need to create a new file for every unique size we make. CAMWorks recognizes these features in their new dimensions and updates the cutting data automatically from the old size to the new size,” Courtney said.

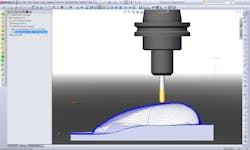

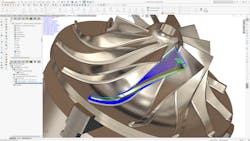

SolidWorks, a suite of 3-D software tools that allows users to create, simulate, publish and manage data, and CAMWorks, a parametric, solids-based CNC programming software system, are part of the portfolio of products offered by HCL Technologies. The products are constantly evolving — most recently, HCL announced a new CAMWorks module for wire electrical discharge machining.

“We use SolidWorks to design the machines and the aluminum molds. We use CAMWorks to fabricate them,” explained Steve Zimmerman, chief information officer for Prent.

Courtney said the sotware hashelped increase Prent’s efficiency. For“As the size of the mounting tool changes, the feature locations change with it, and, as it finds features on a new part, we can have it output operations with our custom settings from the database,” he said.

According to Courtney, the software has helped the company reduce the time it spends on programming specific mounting tools.

Another important feature for Prent is that CAMWorks and SolidWorks are compatible with other software, including an add-on milling package called VoluMill, available through a separate company, Celeritive, Moorpark, Calif., Courtney said.

The ability to work seamlessly with SolidWorks was a big factor in Prent’s adoption of CAMWorks in 2004, when HCL integrated the products. Prent, which employs more than 1,500 people in four countries, also was looking for software that’s well-supported in Southeast Asia, as well as China and Europe, said Zimmerman.

“We looked at several solutions and concluded CAMWorks was the best fit. We could do everything natively in one environment rather than having twoAccording to an HCL spokeswoman, the integration is “an ideal manufacturing enabler.”

Automation means many things to many people, said Maryann Godin, manager for marketing and sales support for CAMWorks/HCL Technologies. For a machinist, it might be having a robot load the machine or deburr parts; but for CNC programmers, automation might mean automatic tool-path generation.

SolidWorks and CAMWorks’ compatibility for tool designers and makers automates their process, she said.

“The CAD and CAM models become one-in-the-same and all CAD and CAM data is stored in single file. There’s no need to maintain separate CAD and CAM files, and there’s no risk of machining an obsolete revision of the part,” Godin said. “In addition, the tool paths are fully associated to the design model and update automatically to design changes, saving valuable time and effort each time engineering design change occurs.”

Zimmerman agreed about the packages’ biggest benefits.

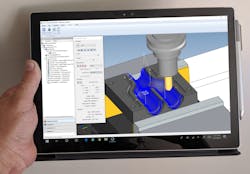

“The biggest benefits are that CAMWorks is integrated right into SolidWorks,” Zimmerman said. “It’s not a separate package that many of the competitors were at the time we purchased it. It’s an easy-to-use tool that functions just like SolidWorks, so it keeps the training to a minimum and is a robust, reliable solution.”

CAMWorks, from HCL Technologies, is available worldwide through a large network of resellers. USA Geometric Americas is an HCL company.

Contact:

USA Geometric Americas Inc., Scottsdale, Ariz., 480-367-0132, https://camworks.com