Wittmann Battenfeld robots gain suction-cup monitoring

W8 Wittmann Battenfeld has upgraded its W8 line of servo robots for parts removal, such as the W843 pro robot shown at top right. Robots in the W8 line are compatible with injection molding machines that have clamping forces ranging from 22 tons to 4,400 tons.

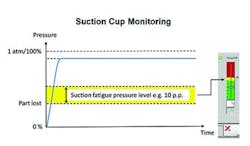

What's new? The ability to monitor wear to suction cups used in end-of-arm tooling (EOAT) for parts removal. The robots' R8 control system now features a vacuum-analysis function that provides an early warning to the operator if the gripper is damaged or the connection point of a vacuum hose has a leak. The operator can set the parameters for the vacuum-analysis function based on the specific surface structures of the plastic part. Shown at bottom right is an R8 robot control system with the relevant screen display and a diagram of the suction-cup monitoring function, bottom left.

Benefits Prevention of downtime and equipment damage. When suction cups wear out, they stop gripping parts, which can lead to machine shutdowns and damage to molds. The vacuum analysis function allows the operator to address the issue before the robot stops functioning properly.

Wittmann Battenfeld Inc., Torrington, Conn., 860-496-9603, www.wittmann-group.com