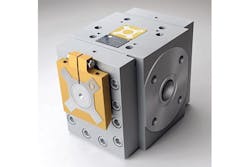

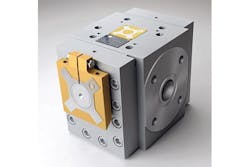

Maag unveils redesigned gear pumps at K show

entrex Maag has updated these gear pumps, which can be added to extruders, to allow them to achieve greater efficiency and versatility, with the ability to handle polymers with viscosities varying by as much as five orders of magnitude. Now in their sixth generation, the pumps are designated as x6, or entrex6.

What's new? The next-generation gear pump, which debuted at the K show. In designing the pump, Maag considered factors such as stress, fluid dynamics and heat flux. It redesigned every component in its pump portfolio, including gears, shafts, bearings and seals.

Benefits Compact size and high flow rates. The efficient pump can operate at reduced speeds, shear rates and temperatures, which reduces residence time. This results in better productivity, higher polymer quality and reduced energy consumption. According to Maag, the new pumps can achieve flow rates up to 50 percent higher than pumps of a similar size, and reduce material recirculation by about 50 percent. Also, due to the pump's enhanced pressure capabilities, finer filter meshes can be used downstream.

Maag Automatik Inc., Charlotte, N.C., 704-716-9000, www.maag.com