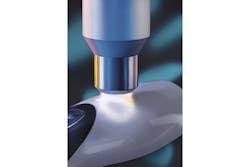

Plasma cell system prepares metal for overmolding work

PT1200 Plasmatreat's new plasma cell includes all of the necessary components for preparing metal for overmolding in applications such as automotive parts manufacturing. Consisting of the plasma generator, robot, control technology, plasma-control unit, plasma jets, cables and gas, the cell can be adapted to suit any conventional injection molding machine. As part of the process, a six-axis robot or a two-axis gantry system positions the metal inlay beneath a Plasmatreat Openair atmospheric plasma jet, which removes contamination from the part's surface and activates the surface chemistry for coating. A second jet applies a functional coating, then the parts are transferred to an injection molding cell, where a robot puts them under an induction heater and then loads them into the mold.

What's new? The system.

Benefits Prevention of delamination and failures at the interface between plastic and metal. The PT1200 process represents an environmentally safer approach than traditional cleaning and priming methods using chemicals. In contrast to other methods, it's also faster, requiring no intermediate steps such as storage or drying.

Hall 11/G04, Plasmatreat, Elgin, Ill., 847-783-0622, www.plasmatreat.com