New in-mold labeling system targets small prototype runs

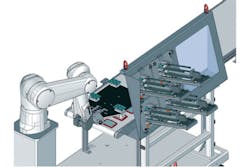

Flexstar H. Müller-Fabrique de Moules SA, Conthey, Switzerland, has launched a new in-mold labeling system that is targeted at small prototype runs and lower-volume production. Flexstar can handle all common shapes and types of containers, lids and labels, including wraparound labels with or without bottom labels, according to the company, which is represented in the U.S. by Fame Technology. Müller integrated a standard Stäubli six-axis robot into the system. The robot can be used with up to four cavities and is configured for dynamic insertion, which means that before the mold is completely open, the robot's gripping arm advances into the machine. The system is suitable for injection molding machines with up to 250 tons of clamping force; additional versions for larger presses are planned.

What's new? The system's ability to insert labels and remove finished parts from either the stationary or the movable half of the mold, depending on whether the products are gated from the inside or from the outside.

Benefits Versatility, low cost and a small footprint for efficient use of floor space. In addition to in-mold labeling, Flexstar can perform minor assembly steps. The use of the standard Stäubli robot yields competitive pricing.

Fame Technology Solutions, St. Charles, Ill., 847-612-6270, www.muller-iml.com