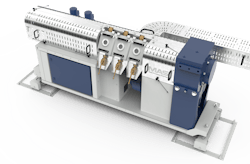

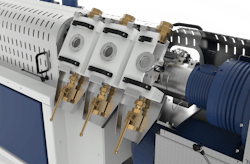

MAS retrofit package provides more effective degassing

Cascade This MAS retrofit package for recycling extrusion lines from MAS Maschinen und Anlagenbau Schulz GmbH, Pucking, Austria, combines the company’s MAS-CDF disc filter with a single-screw degassing extruder. When located downstream of a single- or twin-screw extruder, the package creates a cascade extrusion line, in which the melt stream coming from the disc filter divides into a series of separate streams in a multi-channel melt distribution manifold. This makes it possible to process recycled material with high levels of soft contaminants or heavily printed materials. In the U.S., eFactor3 represents MAS.

Benefits High-quality recycled resin. A cascade extrusion line provides more effective degassing for more homogeneous material density. The package can boost recycling line throughput by 40 to 50 percent and is especially effective at processing PE film flakes.

eFactor3, Charlotte, N.C., 704-944-3232, www.efactor3.com