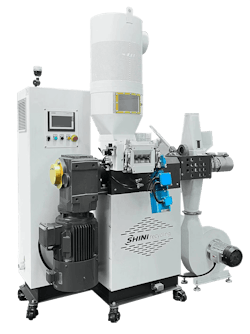

SFP-45, -60 and –70 The 460-volt film pelletizers in this new Shini USA series are equipped with blades built inside the pelletizing chamber to provide precise cutting and uniform pellet size. An HMI, PLC and inverter system match feeding, extrusion and pelletizing. All SFP pelletizers come with two 80-mesh filters. The manual filter changer uses a swing-pod design, and the cycle design produces air flow for the pellets. The SFP-45 is an air-cooled unit, while the SFP-60 and SFP-70 come in air-cooled or water-cooled versions. Depending on the material being pelletized, throughputs range from 44 pounds per hour to 88 pounds per hour for the SFP-45 up to 265 pounds per hour to 330 pounds per hour for the SFP-70 water-cooled pelletizer. The SFP-45 and SFP-60 models have three heating zones, while the SFP-70 has six. Primarily designed for compounders and recyclers, the pelletizers can be easily integrated into production lines.

What’s new? The pelletizers.

Benefits Effective pelletizing. A trim basket optimizes film and flake containment, and effective air flow to separate pellets. The roll feeder is equipped with safety features.

Shini USA, division of Budzar Industries Inc., Willoughby, Ohio, 440-586-3129, www.shiniusa.com

About the Author

Ron Shinn

Editor

Editor Ron Shinn is a co-founder of Plastics Machinery & Manufacturing and has been covering the plastics industry for more than 35 years. He leads the editorial team, directs coverage and sets the editorial calendar. He also writes features, including the Talking Points column and On the Factory Floor, and covers recycling and sustainability for PMM and Plastics Recycling.