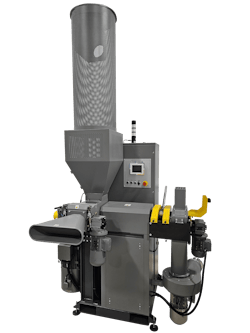

Sasquatch This Advanced Blending Solutions (ABS) repelletizer — a direct extrusion system — supports both inline trim system feed and roll feed, offering the ability to use both simultaneously. It features a large collection chamber for increased pellet transportation.

What’s new? The Sasquatch, released within the past year.

Benefits High-output efficiency with minimal power use and space requirements. Unlike other systems, the Sasquatch requires no pre-processing or size reduction, streamlining the recycling process. With the smallest footprint on the market, it maximizes production space efficiency without compromising performance. Additionally, its built-in trim pulling nip ensures optimal material conveyance into the extruder. Its melt temperature control and enlarged feed entry reduce the risk of bridging. According to ABS, the Sasquatch requires a minimum level of maintenance, and is designed for easy access for cleaning.

Advanced Blending Solutions, Wallace, Mich., 906-914-4180, https://adv-blend.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.