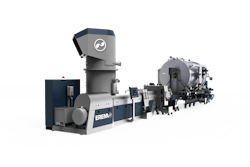

Intarema FibrePro:IV This Erema technology can process shredded PET fiber materials that have been heavily contaminated by spinning oils and turn them back into pellets. It features a new technology for optimizing the viscosity of the PET melt to the precise level that is needed for fiber production.

What’s new? The Intarema FibrePro:IV, shown in June at the Textile & Garment Technology Exhibition in Milan. The technology’s U.S. debut came in June, as well.

Benefits Especially gentle material preparation and efficient removal of spinning oils. Compared with conventional PET recycling processes, the technology allows a longer residence time of the PET melt, providing more time for the removal of the spinning oils and other additives used to improve the handling of the fibers during manufacturing. Thanks to the process, the Intarema FibrePro:IV produces rPET that can be reused in proportions of up to 100 percent for the production of very fine fibers.

Erema North America Inc., Ipswich, Mass., 978-356-3771, www.erema.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.