Patent Report: High-temperature reactor recycles PET

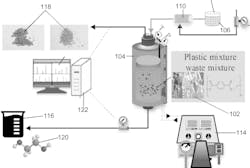

PET depolymerization. A patent application filed by the University of Wyoming and Washington State University describes a high-efficiency, low-energy and environmentally friendly method of recycling PET waste.

Current methods of PET recycling all suffer drawbacks; separation and classification of plastics can be a hurdle to efficient mechanical recycling; chemical recycling relies on toxic organic solvents; and incineration releases harmful gases into the atmosphere.

The application says its method works by attacking the –O– ester linkage in PET.

This is accomplished by loading a supercritical, high-temperature reactor with PET and deionized water. CO2 is injected into the reactor, and then the reactor is heated to a reaction temperature for a specified time.

The application explores the relative merits of varying input levels, investigating feedstock weight ratios of PET to deionized water ranging from 1:10 to 1:30, injection pressures up to 700 psi, temperatures as high as 464 degrees Fahrenheit and time intervals ranging from 15 minutes to 2 hours.

The results showed that CO2 can be an effective hydrolysis catalyst for PET. After the reactor tank returned to room temperature and was unsealed, terephthalic acid and ethylene glycol, both of which may be a liquid product, a solid product or both, was collected from the reactor.

The patent application noted that the degradation ratio of the PET can reach as high as 100 percent with a PET-to-water feedstock weight ratio of 1:30 at 428 degrees Fahrenheit, with an initial CO2 pressure of 700 psi for 1.5 hours.

As an added benefit, experiments found that the recovered CO2 could be used for subsequent reaction cycles, reducing consumption of input materials.

Patent application 20210340351; published Nov. 4.