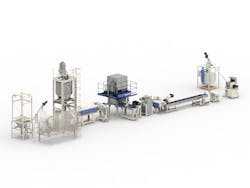

BB Engineering system recycles PET

VacuFil The BB Engineering VacuFil liquid-state-polycondensation system processes PET waste, making it suitable for use in high-end filament and textile fiber products. It achieves a high degree of melt homogeneity via drying; controlled plasticizing; gentle, large-scale filtration; and controlled vacuum degassing. The system includes an inline viscosity measuring unit connected to a vacuum system. This allows the intrinsic viscosity (IV) of the resin to be continuously adjusted to create the specific type of recycled polyester required for each downstream application, such as spinning. The system can process bottle flakes, agglomerated spinning waste or a combination of the two into PET granulate, or it can directly feed downstream processes. The modular system provides throughputs from 660 pounds per hour to 6,600 pounds per hour.

What’s new? The system, and its key component, the Visco+ vacuum filter. The vacuum unit removes volatile contamination and ensures a controlled increase in IV.

Benefits Recycled PET that has the same characteristics as virgin PET. The liquid-state-polycondensation system boosts the IV faster, more simply and less expensively than many existing methods. Additionally, the system eliminates the need for energy-intensive predrying.

BB Engineering GmbH, Remscheid, Germany, 49-2191-9510-100, www.bbeng.de