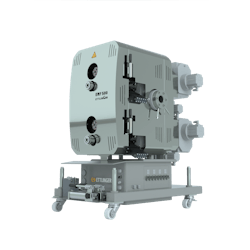

Melt filter tackles contaminated plastics for recycling

ERF500 Ettlinger’s ERF500 continuous melt filter is targeted at medium-sized recycling lines that process plastics with contamination levels as high as 18 percent. It removes contaminants such as aluminum, paper, rubber, paint and unmelted polymers. The device features a rotating, perforated filter drum; the melt flows from the outside to the inside of the drum, passing through dual filters with a total surface area of 487 square inches. A scraper removes contaminants from the surface of the filter and feeds them to the discharge system.

What’s new? Generation 2, which has numerous upgrades. The company has completely redesigned the inlet, crosshead, drive shaft and exit flange of the ERF500 to reduce pressure. A new rigid, 60-micron screen provides finer filtration.

Benefits Greater throughput. The redesign has boosted the melt filter’s maximum hourly throughput to 13,228 pounds, an increase of about 20 percent over the prior model. The continuous cleaning and large surface area of the drums provide constant pressure during operation and reduce the need for operators to change filter screens, allowing recycling lines to run uninterrupted for weeks or even months. Additionally, the finer filtration allows recycled HDPE and LDPE to be processed in blown film lines.

Ettlinger North America LP, Tyrone, Ga., 770-703-8541, www.ettlinger.com