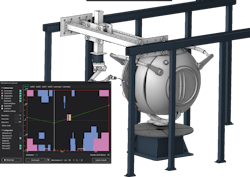

Ency Ency Software’s CAD/CAM system is designed to allow users to set up and machine even the most complex, multi-operation parts without errors. It offers three-axis, 3+2 and full five-axis modes.

What's new? Numerous upgrades as part of Ency 2.0. Updates include the ability to support internal surface machining operations like rotary finishing, 6D contouring, and 5D surfacing; accelerated geometry selection; enhancements to improve additive manufacturing applications; an artificial intelligence (AI) feature that automatically generates complete machining processes and an advanced drilling feature that automatically reduces feed rate at hole intersections. Other new features include a new collision avoidance algorithm that offers faster, more stable path planning; and streamlined user access to tutorials, project libraries and collaborative workspaces. Also, robot setups, including configurations like robots on gantries, can now be defined automatically.

Benefits Ease of use; faster feed rates; reduced time to set up and create machining projects; improved control and tool life; and enhanced surface quality. According to its manufacturer, Ency 2.0 makes it easy for users — even novices — to program complex parts and processes, including robotic cells.

Ency Software Ltd., Limassol, Cyprus, 357-25-054746, https://encycam.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.