Valve gates with replaceable inserts withstand millions of cycles

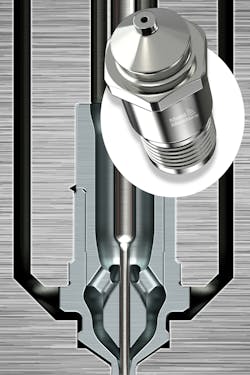

Accu-Valve Mold-Masters’ Accu-Valve cylindrical valve gates for hot-runner systems feature continuous 360-degree pin guidance in close proximity to the gate to ensure gate-component alignment. Compatible with both commodity- and engineering-grade resins, the valve gates are available in a variety of versions and sizes to meet the demands of many applications in markets that include the medical, packaging and personal-care industries.

What’s new? The GX valve gates. They feature a replaceable gate insert and integrated valve pin guide. The compact 1mm gate can fit on a wide range of parts. Compatible with Mold-Master’s Master- and Summit-series hot-runner systems, the GX gates are especially appropriate for commodity and polyolefin resins, including PP, PE and TPE.

Benefits Simplified maintenance and reduced downtime. Made to perform for millions of cycles, the valve gates can be used in packaging and fast-cycling application. They are designed to minimize wear. The gate inserts can be replaced easily, so molders are spared the need for traditional gate-hole rework and welding as the component wears. This not only reduces maintenance, but also ensures that all components continue to maintain the same levels of tolerance and concentricity.

Mold-Masters, Georgetown, Ontario, 905-877-0185, www.moldmasters.com