Oerlikon HRSflow looks to help molders, mold makers with supply-chain issues, challenging resins

By Karen Hanna

When it comes to hot-runner systems, molders and mold makers want a little bit of everything, system suppliers say.

“Of course, there is always the obvious and constant cost pressure put on all suppliers within the manufacturing supply chain. In addition to this, processors are using more difficult and demanding resins to produce higher-performing parts,” explained Robert Harvey, Oerlikon HRSflow’s North American sales director. “These resins may have higher levels of loading of fillers, or corrosive components such as flame retardants, which can present challenges to the hot runner.”

Tooling design trends also pose challenges, he said.

“Modular and family tooling applications are being seen more and more for the purpose of reducing total tooling costs. This puts a demand on the hot runner to be flexible for differing part weights, wall sections and processes.”

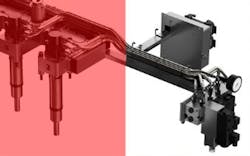

The S Series Cylinder hot-runner systems can be used in applications that involve low shot weights; multicavity molds; small, technical parts; or components as thin as 1mm. Possible parts include consumer goods; electronic components; and automotive parts such as emblems, interior switches and knobs.

With a minimum nozzle pitch of 37mm, the systems are designed to offer a compact solution and reduced pitch.

They are available in two layouts, known as the basic and adjustable versions. The height of the basic version is 62mm, compared with 70mm for the adjustable version.

Oerlikon HRSflow planned to display the S Series Cylinder hot-runner system at Fakuma, where it was slated to help make hydration reminders — PP devices that can be attached to bottles or glasses to remind users to drink regularly.

The MSR, which ensures accurate pressure distribution during the packing phase, is suitable for use with hydraulic hot-runner systems with electrovalves. The MSR provides an easy way to mechanically adjust the opening position of the pin at a fixed value, allowing the molder to adjust the pressure drop for each nozzle independent of other nozzles. Via a graduated-scale adjusting screw, users can specify the individual oil volume; the valve-gate system uses the information to bring the needles into the intended positions. In this way, the pressure distribution during the packing phase can be controlled.

The MSR can be used with family molds. When combined with Oerlikon HRSflow’s FLEXspeed system, the speed of the pin also can be adjusted.

“We have recognized that numerous quality problems on parts that occur during the injection process can be positively affected by the management and correct positioning of the pin,” said Stephan Berz, VP of sales for Oerlikon HRSflow. “The new MSR is the result of our developments to make the pressure drop proportional to the opening stroke of the pin. It allows for easy pin adjustment even with hydraulic actuation.”

According to Oerlikon HRSflow, the MSR can be installed in existing equipment in about 10 minutes, and the procedure does not require dismantling the mold or modifying the hot-runner cutout.

Karen Hanna, senior staff reporter

Contact:

INglass USA Inc., Byron Center, Mich., 616-228-6900, [email protected]

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.