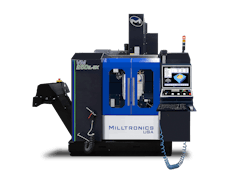

Milltronics debuts 5-axis vertical machining center

VM250IL – 5X Milltronics’ first true five-axis vertical machining center is the largest in its machining center stable and features a rotary table, the company’s Inspire+ control and a 19-inch touch screen, as well as chip conveyor chip-removal and chip-washdown systems. Optional add-ons include a digital set-up assistant, thermal head mapping, spindle chiller, electrical cabinet air conditioning and programmable air-blast and spray-mist systems. The machining center is appropriate for makers of small molds for products such as critical medical equipment.

What’s new? The VM250IL – 5X, along with the Inspire+ control. Milltronics introduced the technologies to the North American market in September at IMTS.

Benefits Five-axis capabilities. In addition, the control provides improved surface finish and cycle times, and an advanced proprietary motion engine.

Milltronics, Indianapolis, 888-999-1440, https://milltronics.com

Vital Statistics

|

Machine footprint |

About 7.2 feet by 8.8 feet |

|

Machine height |

About 10.3 feet |

|

Machine weight |

13,068 pounds |

|

Travel dimensions |

30 inches by 20 inches by 20.5 inches |

|

Table working surface |

9.8 inches in diameter |

|

Maximum weight on table |

440 pounds |

|

Spindle speed |

15,000 revolutions per minute (RPM) |

|

Tool capacity/type |

40/double arm |

|

Maximum tool diameter |

3 inches |

|

Maximum tool length |

About 9.8 inches |

|

Maximum tool weight |

15.4 pounds |

|

Maximum cutting feed rate |

500 inches per minute (IPM) |

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.