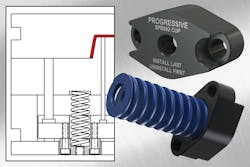

Spring Cups These new Progressive Components ejector system components are designed to aid mold assembly, which can be cumbersome and unsafe when dealing with pressure from springs. The Spring Cups allow for all ejection components to be installed first, before the ejector springs are installed, so technicians can dry-cycle the injector system to verify that they have assembled components correctly with no binding issues. After they’ve confirmed that everything is set up as it should be, technicians can then install the springs, and bolt in the Spring Cups last.

What’s new? The Spring Cups, announced in April.

Benefits Safer and easier installation of spring-loaded ejector systems. The Spring Cups help optimize valuable space within molds and prevent binding issues from causing damage to ejector pins, sleeves, lifters and other components. The Spring Cups also speed installation. Typically, mold makers have to assemble an entire mold half without springs, check to be sure the ejector system is moving smoothly, then disassemble the mold, add the springs and reassemble the mold. But with Spring Cups, after they verify the ejection movement is smooth, they can complete the mold’s assembly.

Progressive Components, Wauconda, Ill., 847-487-1000, https://procomps.com/

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.