Stainless steel expands capabilities for Mantle 3D printers

NPE Booth S27055

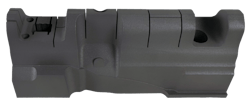

3D printers Mantle’s hybrid metal 3D printers can be used to create tools with conformal cooling for prototyping and production applications. The company’s TrueShape technology deposits a metal paste onto the build plate, and each complete layer is dried to make it firm. The near-net shape is then machined into its final dimensions with high-speed cutting tools. The dried paste can be machined much more quickly than solid metal. To achieve final hardness, the finished part is then sintered in a Mantle furnace.

What’s new? Mantle’s 420 stainless steel, which will be available in the second half of this year. A simple software update will allow all Mantle P-200 printers to use the new steel, and no hardware modifications or additional components will be required.

Benefits New potential applications. Mantle’s 420 stainless steel has hardness comparable to the currently available H13 tool steel (52 HRC) but adds superior corrosion resistance. This makes it ideal for use in corrosive molding applications. Mantle says its customers can produce high-quality tools, molds and dies from 420 stainless steel with less than half the cost and time traditional manufacturing techniques require.

Mantle Inc., San Francisco, 415-655-3555, www.mantle3d.com

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.