Software optimizes molding simulation

Sigmasoft Virtual Molding software provides 3-D simulation of melt flow, heat flux and part warpage for injection molding and can be used to improve mold design and production. Autonomous Optimization, a tool within Sigmasoft software, uses a virtual design of experiments to test a wide range of variables to find the best solution.

A user defines a specific objective — for example, achieving balanced filling of multiple cavities. The user can set target values and adjust the degrees of freedom for each variable to be tested. Users also can set constraints on factors that can’t be adjusted, said Vanessa Frekers, manager of marketing and engineering.

In general, the system can take into account all parameters of the part geometry, runner system, tempering system and mold, as well as all process parameters, she said.

At the touch of a button, Autonomous Optimization runs numerous simulations, changing each of the variables incrementally while keeping the user’s end objective in mind. The result of each simulation is plotted on a chart. The user can compare and evaluate which changes yield results closest to the objective, Frekers said.

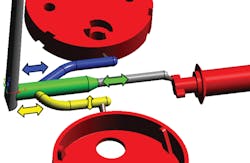

At Fakuma, Sigma Engineering demonstrated how Autonomous Optimization can be used to determine the ideal hot-runner design for a family mold featuring cavities with different dimensions. The mold was for making parts with different volumes and wall thicknesses; balanced filling was the desired objective.

The company selected four different geometry parameters that could be adjusted through simulation relating to the design of the main sprue and sub-sprues feeding each mold cavity. In numerous simulations, the software changed the thickness of the main sprue in specific areas, adjusted the radius of the bottom sprue and changed the starting points of the lateral sprues branching from the main sprue. Autonomous Optimization determined the mold filling time for each simulation, Frekers said.

The software identified an ideal dimension for each sprue and determined which specific dimensions best provided balanced filling. The simulation revealed a hot-runner design in which the filling pressure could be less than 8,702 pounds per square inch and the cavities were filled within 0.1 second of each other.

As specified, the software did not change related parameters such as melt temperature, pack and hold times and cycle time.

Determining the optimal gate location or achieving the fastest possible cycle time are two common goals for injection molders. Other objectives could include: eliminating air entrapment during injection; finding the lowest injection pressure that doesn’t create a weld line in the part; determining the best gate and venting locations; discovering the best material to produce a part; or ascertaining the best location and temperature for electric heaters within a mold.

Sigmasoft’s simulation software is best run on a computer with a quad core processor. It runs on both Windows and Linux systems.

Contact

Sigma Plastics Services Inc.

Schaumburg, Ill., 847-558-5600,

www.virtualmolding.us