Webinar

Sign up for our May 6 webinar on using cobots in plastics processing.

China is eating our lunch when it comes to investment in automation and industrial robotics.

China became the world’s largest robotics market in 2019, both in annual sales and the operational stock of robots. In 2023, Chinese factories installed more than 276,000 new industrial robots, which was 51 percent of worldwide demand. There are now about 1.75 million industrial robots working in China. Also of interest: 47 percent of these new robots are from Chinese manufacturers, a jump from 28 percent in previous years.

Japan is the second biggest buyer of industrial robots with 9 percent of the world’s total installed in 2023; the U.S. was third at 7 percent, according to a report on new installations from the International Federation of Robotics (IFR), part of the German-based VDMA trade group.

We have an outdated idea that China should not need robots because it has an unlimited supply of workers willing to show up and work for a pittance. That may have been somewhat accurate at one time, but the manufacturing workforce in China is actually decreasing due to an aging population and growing competition from service jobs.

What should plastics processors do? Everyone rushing out to buy a robot is not the answer. A better approach would be to make automation an integral part of every step in your plant. Yes, you may have to buy a robot — or robots — to make that happen. But that is a small price to pay for improving your productivity, quality and operational effectiveness.

PMM is presenting a webinar Tuesday at 2 p.m. Eastern titled “Integrating Automation Into Plastics Manufacturing by Adding Collaborative Robots.” Presenters are Ryan Lillibridge, vice president at Mission Design & Automation, and Brian Connor, Program Manager for Integration & OEM in the Americas at Universal Robots.

The presenters will discuss how employing cobots can be a great first step in automation adoption; the competitive advantages of working with systems integrators to evaluate your current process and support your automation efforts; and successful applications stories.

When it comes to modernizing the manufacturing infrastructure, there is plenty of work to do.

The Association for Advancing Automation (A3) in late March sent recommendations to Congress that included:

- Establishing a central government robotics office and robotics commission to coordinate robotics policy, innovation and industry collaboration.

- Implement tax incentives to drive adoption.

- Make government a leading adopter in integrating robotics into their operations.

- Expand workforce training, including investing in STEM education and upskilling programs.

- Fund academic research and commercial innovation.

- Develop new industry standards.

Jeff Burnstein, president of A3, said: “The United States is at a critical moment in shaping the future of automation. While AI is a major focus, we cannot afford to fall behind in robotics. Our vision for a national strategy provides a roadmap for strengthening U.S. competitiveness, innovation and workforce readiness.”

Sounds like a good place to start.

I’m headed to Automate 2025 in Detroit next week, where there is always a dazzling display of the latest and greatest robotics from suppliers around the world. Watch for a report next month.

About the Author

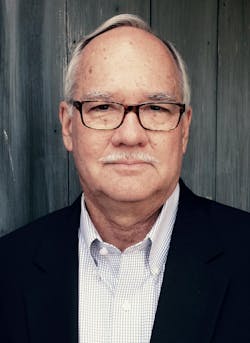

Ron Shinn

Editor

Editor Ron Shinn is a co-founder of Plastics Machinery & Manufacturing and has been covering the plastics industry for more than 35 years. He leads the editorial team, directs coverage and sets the editorial calendar. He also writes features, including the Talking Points column and On the Factory Floor, and covers recycling and sustainability for PMM and Plastics Recycling.