Staübli Robotics demonstrates new PF3 AGV

By Bruce Geiselman

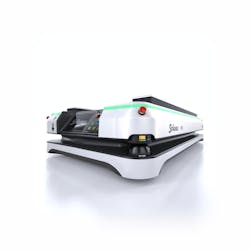

The latest automated guided vehicle (AGV) from Staübli Robotics is compact and easy to maintain, according to the company.

Shown for the first time in North America at Automate 2023 May 22-25 in Detroit, the PF3 AGV can move a maximum payload of 3 tons.

According to the robot manufacturer, AGVs have become integral to industrial intralogistics by doing the heavy lifting in manufacturing facilities.

“In the plastic industry, you can use it obviously to move the mold,” said Sebastien Schmitt, the company’s robotics director for North America. “We see more and more that the industry doesn’t want to do the hanging of molds and going above the area. They’d rather put it on the floor and move it directly through AGVs. That is a solution that we can provide, going to the storage area and then back to the molding machines and moving back and forth.”

In addition to the PF3, Staübli has AGVs capable of moving up to 500 tons. However, the larger models require more engineering and customization. The PF3 is ultra-compact and standardized, Schmitt said.

“Being standardized, it’s able to be mass-

produced with shorter lead times, and it’s more cost-competitive,” Schmitt said.

The PF3 measures 68.9 inches by 38.2 inches, with a height 15.7 inches with a lift unit or 13.8 inches without one. The size allows it to operate within narrow spaces on a factory floor, easily maneuvering around obstacles and carrying out tasks with a position precision of plus or minus 5mm, according to the company.

Its standard software interfaces and touch panel provide an ergonomic operator experience, according to the company.

Safety features on the PF3 include a 360-degree human safety scanner, collision-avoidance system, five emergency stop buttons and an LED strip that communicates the AGV’s status.

To simplify maintenance, the parts needed to maintain the AGV are located in a drawer along the sides of the unit. They can be changed in minutes, according to the company.

Bruce Geiselman, senior staff reporter

Contact:

Stäubli Corp., Duncan, S.C., 864-486-5421, www.staubli.com

About the Author

Bruce Geiselman

Senior Staff Reporter Bruce Geiselman covers extrusion, blow molding, additive manufacturing, automation and end markets including automotive and packaging. He also writes features, including In Other Words and Problem Solved, for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He has extensive experience in daily and magazine journalism.