Patent Report: Continental Structural Plastics' invention makes RTM faster

Resin transfer molding. The U.S. Patent and Trademark Office awarded a patent to Continental Structural Plastics Inc., Auburn Hills, Mich., for a resin transfer molding (RTM) method with rapid cycle times and improved part quality.

RTM is commonly used to fabricate composite structures for automotive and aerospace applications, according to the patent. It involves placing a fiber layup, such as graphite, into a mold. The mold is closed, sealed, heated and placed under vacuum. Resin is injected into the mold to impregnate the fiber. The mold is then held at a temperature sufficient to cure the resin.

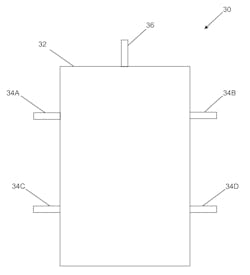

Molds used for RTM have one or more injection ports for introducing the resin; multiport molds are typically used for larger parts that have a longer processing time.

“A common problem encountered during the RTM process is a non-uniform flow of the resin, where the resin experiences a change in viscosity as the resin travels away from the injection point. Furthermore, … as the time of processing progresses, the pressure and temperature experienced by the resin decreases as a function of time,” the patent states. This can result in part defects.

Continental Structural Plastics’ new method requires a mold with multiple injection ports that allow resin to be injected in a staggered fashion.

“The temperature and pressure applied to the mold are controlled during injection to … promote rapid filling of the mold cavity. The injection ports are activated for injecting the resin in any order of individually, in groups, or pairings. Fibers are readily added to the mold separately or within the resin.”

The staggered introduction of resin in the mold provides for an improved pressure and temperature profile versus existing RTM processes that simultaneously inject the resin.

“The staggered introduction of resin … provide[s] for improved product yields with fewer formed part defects resulting from non-impregnated portions, thereby improving the quality of the molded product. Furthermore, product cycle time is also reduced,” the patent says.

The new method slashes cycle times from approximately 10 to 60 minutes to 3 to 5 minutes.

Resins that can be used in the process include epoxy, urethanes, polyesters and vinyl esters. Appropriate fibers include glass, carbon, other synthetic fibers and natural fibers such as coconut, bamboo, sugar cane and banana skin fibers.

Patent 11,247,415; issued Feb. 15