Netstal upgrades Elion MED injection molding machines

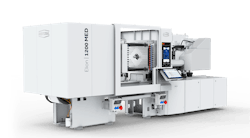

Elion Designed for applications involving disposable medical items, such as pipettes, Petri dishes and blood collection tubes, as well as insulin pens and numerous other items, the injection molding machines (IMMs) in this all-electric Netstal series are appropriate for clean rooms up to class ISO 7 in standard configuration. They have clamping forces ranging from around 90 tons to 315 tons. According to the company, they are consistent, flexible, reliable and user-friendly; also, their energy-recuperation system makes them energy-efficient.

What's new? Upgrades to the series. New features and accessories include a quality-monitoring system, redesigned toggle lever, injection gearbox with a compact metering drive and two-part control cabinet; the new machines also have a modified protective cover and are significantly shortened. Named for its clamping force in kilonewtons, the Elion 1200 MED is one of the first Elion IMMs that Netstal plans to upgrade in stages, beginning with four versions with clamping forces of about 135 tons and 197 tons. At the K Show, an Elion 1200 MED, paired with a six-axis robot, will use a four-cavity mold with an innovative index technology and individual, servo-electrically controlled valve gate nozzles to make autoinjectors in a cycle time of 12 seconds.

Benefits Greater efficiency, along with speed, precision and assurance of production quality. With the upgrades, the Elon machines are more compact, produce virtually no emissions, and can maintain consistently high speeds at high pressure in continuous operation for many years. Also, the clamping unit area offers better accessibility for maintenance work.

NetstaL Inc., Hebron, Ky., 513-987-7516 www.netstal.com