Chen Hsong upgrades controller on SM-V IMMs

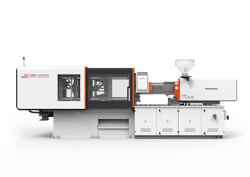

SM-V The servo-hydraulic injection molding machines in this line from Chen Hsong have clamping forces from 66 tons to about 1,818 tons, and feature an advanced toggle design. Options include an integrated hot-runner system, gas-assist injection, additional hydraulic core pulls and an electric screw drive for high-speed and on-the-fly operations.

What’s new? A 15.6-inch touch-screen controller from B&R Industrial Automation, which replaces a standard HMI from the same supplier.

Benefits Faster processing speeds. According to the company, the machines are very reliable. The new controller offers sufficient computing bandwidth for closed-loop calculations and provides precision, repeatability and flexibility for programming operational sequences. The injection molding system provides various reports for production, settings, alarm records and logs of operational settings, and can be linked to cloud-based services and participate in the Internet of Things.

CH America, Torrington, Conn., 860-840-7070, www.ch-america.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.