NPE Booth W1101

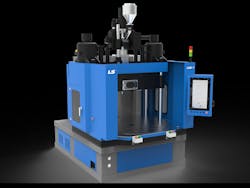

LSG-VL LS Mtron’s line of hybrid vertical presses includes 13 models of injection molding machines ranging from 35 tons to 660 tons, with options for vertical or horizontal injection, as well as rotary table, shuttle or single-station designs. The servo-pump system of the LSG-V series can cut energy usage 65 percent to 70 percent.

What’s new? The LSG-VL variant, which is aimed at the electric vehicle (EV) battery market. The “L” stands for “Low,” referring to the machine’s low table height. At NPE, a 170-ton LSG-VL machine will be molding an EV component.

Benefits Improved ergonomics for machine operators producing EV components. The LSG-VL shares many aspects of the LSG-V line, including the use of four tie bars for greater stability. It also offers reduced cycle times by enabling operators to perform take-out and insertion processes simultaneously. The LSG-VL’s large 18-inch multi-touch Keba controller provides easy cycle analysis and unit conversion.

LS Mtron Injection Molding Machine USA, Duluth, Ga., 470-724-2263, www.lsinjection.com/us

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.