Patent Report: Arburg invention prevents mold tilting

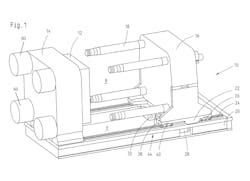

Mold closing unit. A mold closing unit for an injection molding machine that prevents the mold from tilting earned a patent for Arburg GmbH + Co. KG, Lossburg, Germany.

Traditionally, mold mounting plates have a large mass that severely loads the drives, according to the patent. As the mold mounting plates move, tilting movements can arise, in particular during displacement of the mold mounting plates. “As a consequence of the resultant forces, a parallel mold closure and parallel movement of the mold mounting plates during closing/opening of the mold is not assured,” the patent states.

Such tilting movements can damage the mold closing unit, the mounting plates, the drive and the entire injection molding machine. This is even more likely if the drive systems are arranged asymmetrically within the machine frame to allow easier access to the mold clamping space.

Arburg’s mold closing unit includes a machine bed, a stationary platen and a drive mechanism that moves another platen along a slide with guide shoes. The drive mechanism has at least one gear rack drive driven by at least one motor that is affixed to the slide. It also has at least two gear racks that are fixedly connected to the machine bed. This arrangement reduces the occurrence of tilting torques, ensuring the safe operation of the mold closing unit.

“By the use of at least two toothed rack drives, it is possible to prevent the tilting [movements] and the tilting forces associated with them due to an uneven weight distribution of the movable mold mounting plate in relation to the guide elements,” the patent states.

The patent also describes a plurality of load sensors mounted in various locations that accurately detect tilting forces, allowing the machine’s intelligent drive motor control to take steps to counteract such forces.

Furthermore, in order to provide unhindered access to the mold clamping space, the drive mechanism is arranged in the plane of the machine bed, beneath the support elements and the mold mounting plates.

Patent 10,974,428; issued April 13