Conair system uses RFID tech to send resin to the right destination

Line proofing system Conair’s new system is used with the company’s Resin Selection System (RSS), conveying systems and its new SmartFLX conveying control to ensure the correct resin is supplied to each destination receiver.

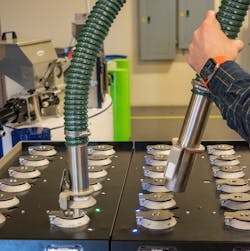

What’s new? Radio-frequency identification (RFID) technology. Each material port on the RSS table is connected to a specific resin supply and associated with an RFID antenna beneath the tabletop. The SmartFLX control tracks all resin sources, along with their RSS ports and unique RFID antenna addresses, in a material source/destination database. Above the RSS table, the flexible tubes that go to destination receivers are equipped with steel connection handles that contain uniquely coded RFID chips. The control uses the wireless signals between the tubes’ RFID chips and the RSS ports’ antennas to verify each connection. The system guides the user via color-changing LEDs to make the correct connections and flashes a red light if the operator tries to make an incorrect connection. Similarly, the system can guide operators through the line-purging process for material changes.

Benefits Simple, error-proof resin distribution. The color-changing lights make the system easy for operators to use.

Conair Group, Cranberry Township, Pa., 724-584-5500, www.conairgroup.com