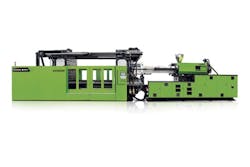

Yizumi-HPM unveiling servo-hydraulic machine

DP-N

Features include controls from Keba and extended rigid sliding shoes to support the moving platen. All the models in the series come with a choice of injection units in various screw sizes. Examples of products that the machines can manufacture include automotive bumpers and grilles, television frames and air-conditioner panels, as well as deep-cavity parts, including garbage bins and washing-machine drums.

What's new? The series, with presses ranging from 550 tons to 4,000 tons. At NPE2018, Yizumi-HPM plans to show a machine that is capable of performing the FoamPro microcellular foam injection molding process based on the MuCell technology from Trexel Inc., Wilmington, Mass. It will be making a foamed briefcase (inset photo) measuring about 22.4 inches by 15.7 inches by 1.6 inches and weighing about 1.9 pounds.

Benefits Accurate, reliable, stable and energy-efficient performance, as well as compact size. Compared to traditional drive systems, the machines' Ecoservo drives and piston variable-pump systems require about 56 percent less energy. Also, because there is no contact between the movable platen and tie bars, mold movement is faster. With their high-speed cylinders and synchronous locking nut mechanisms, machines in the DP-N series have short dry cycle times, making them especially productive. To ensure the clamping unit performs reliably, the tie bars are designed with uniform stress distribution. The machines have mold-open repeatability of within 0.1mm and part repeatability to within 3 percent.

Yizumi-HPM Corp., Iberia, Ohio, 740-382-5600, www.yizumi-hpm.com