Lumina molds solid, foam parts

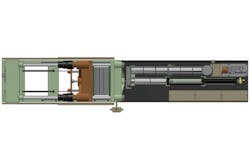

Lumina MP800 Designed to fill the gap between high- and low-pressure injection molding machines, Wilmington Machinery's Lumina MP800 is a hybrid model with a hydraulic press and an electric extruder drive. This 800-ton, two-platen press has a linear-bearing support and guidance system. Applications include materials-handling products such as pallets, bins and crates; enclosures for utilities and electronics; and interior and exterior automotive parts. With a mold space of 98 by 68 inches, it has a stroke of 108 inches, a clamp speed of 2,000 inches per minute and cycle times ranging from 30 to 90 seconds. The two-stage unit has a 152mm extruder with throughputs up to 2,000 pounds per hour, an accumulator shot capacity of 44 pounds, and an injection-pressure capability of 10,000 pounds per square inch. The illustration shows the machine as viewed from above.

What's new? The ability to accept hot-runner molds, process 100 percent recycled materials (even in flake form), and produce foam parts with thinner walls.

Benefits The flexibility to mold both solid and foamed large parts, and cost reductions derived from directly injecting low-cost, inert gases to produce foamed parts.

Wilmington Machinery Inc., Wilmington, N.C., 910-452-5090, www.wilmingtonmachinery.com