I visited my first injection molding plant in the early 1990s — a micromolder running what was described as a lights-out operation. I was impressed.

Up to that time, my manufacturing plant visits had consisted of forays into an automobile assembly plant, a tire factory and the location where Corvette bodies were built.

We have generally considered automation to be getting material to the processing machine and taking parts away from the machine. In the case of injection molding, pulling the part out of the mold can be a key task for automation.

New machinery and control systems displayed at the K 2025 show that the plastics processing industry is on the verge of taking a giant step forward with automation.

The micromolding plant I visited 30 years ago still needed operators to set up, monitor and adjust the molding machines as well as perform quality checks on parts. The latest generation of machinery does much of that.

The machine has been the missing link, but thanks to Industry 4.0, smart factory technology, artificial intelligence (AI) and the shortage of skilled workers that forced machinery makers to focus on the problem, solutions are here.

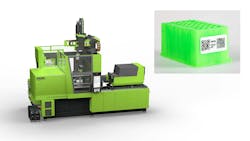

The Engel Group showcased what it described as the world’s first autonomous, self-regulating injection molding cell. Engel CEO Stefan Engleder said the cell autonomously produces high-quality parts with AI support.

Instead of adjusting machine parameters, the operator specifies desired product characteristics and the molding machine controls all process settings. The company said that thanks to AI-supported initialization, it will soon be possible to determine quality features directly.

What does this mean for processors? Traditional automation will bring material to the processing machine and take away finished parts. During initial setup, the machine is told what it must produce. That’s about it.

The molding machine automatically compensates for any fluctuation in the process, even with significant fluctuations such as those found running 100 percent recycled material.

Setup time is reduced from hours to minutes.

In addition to requiring less labor to monitor machines, material savings are gained because manual trials to optimize quality are no longer necessary. Engel estimates savings of up to 5 percent. That translates to several thousand dollars per year for a production volume of 1 million parts per year.

Eliminating quality optimization trials also reduces scrap.

Engel introduced Inject 4.0 — its version of Industry 4.0 — 10 years ago and that has now evolved into Inject AI.

One component of Inject AI is the new Engel Virtual Assistant, an AI-based, 24-hour assistant that answers technical questions from all Engel documentation and generates checklists and instructions tailored for each individual production cell. It lets the user chat directly with the documentation for their own machine.

Engel said it has about 15,000 machines networked worldwide that are already using Inject 4.0 for help with design, sampling, production, process optimization and maintenance. Inject AI is the next evolutionary step in increasing the use of AI, according to Engel CTO Gerhard Dimmler.

Engel said its AI-supported systems turn a complex processing data into clear, immediately actionable instructions, eliminating the need for staff to analyze production curves.

Other machinery companies also showed technology systems to reduce labor and simplify the molding process.

Haitian introduced X-Injection, a deep AI-based system to set up, optimize and monitor the molding process.

Extrusion equipment manufacturer Reifenhåuser introduced its AI-based Next product to integrate AI with advanced learning and machine data. By linking machine data to a central knowledge hub and learning platform, Reifenhåuser said the system will allow real-time troubleshooting, process optimization and data-driven decision making.

Shibaura Machine showed its AI-powered Virtual Machine Expert, which monitors the production process and proactively detects potential component issues. The company said this can reduce unplanned downtime.

Shibaura also introduced its Leo (Line Efficient Optimizer) software, which gives real-time advice and assistance to operators.

Stork showed its Stork Injection Control (STIC) software, which corrects for material variations in real time and guarantees shot-to-shot accuracy, according to the company.

Wittmann demonstrated its TEMI+ MES to integrate machines in the plant, iMAGOxt energy management system and AIM4Help web portal using AI for first-level service and troubleshooting.

Are we any closer to real light-out processing? I think so. Are processors benefiting from this rush of new technology? Definitely, yes.

About the Author

Ron Shinn

Editor

Editor Ron Shinn is a co-founder of Plastics Machinery & Manufacturing and has been covering the plastics industry for more than 35 years. He leads the editorial team, directs coverage and sets the editorial calendar. He also writes features, including the Talking Points column and On the Factory Floor, and covers recycling and sustainability for PMM and Plastics Recycling.