Improved ram extrusion system makes thin panels

Ram extrusion. Rochling Engineering Plastics, Orangeville, Calif., seeks to patent an invention that it claims overcomes many of the difficulties associated with using ram extrusion to manufacture thin panels from ultra-high-molecular-weight (UHMW) resins.

The patent application cites numerous problems with processing UHMW polymers via ram extrusion, including a variety of defects in the finished product that are associated with such resins’ sensitivity to shear forces and high temperatures.

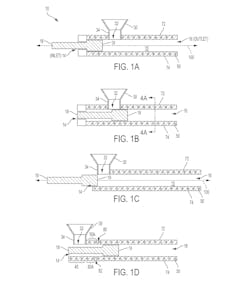

Additionally, the die itself can further contribute to product flaws. “To produce a large flat panel of UHMW polymer resin, a die having a large top and bottom surface is employed,” the application states. “Such a die may experience increased internal pressures which are difficult to control, especially for panels having a thinner profile. For example, the large pressures can cause the center region of these wider dies to bow, thus producing a panel having a greater thickness in the middle.”

To prevent these issues, the system delivers precisely metered amounts of resin across the width of the die inlet and is configured to move the resin through multiple thermal zones in the die.

The system is capable of continuously and rapidly extruding wide, thin panels (as thick as 1.5 inches) from UHMW resins, such as PE, polyamide, PET and polytetrafluoroethylene, according to the application.

Patent application 20200009778; published Jan. 9