Reifenhäuser upgrades PAM automation system

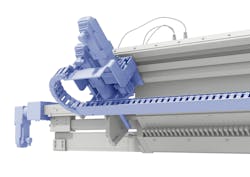

PAM This Reifenhäuser system — the name stands for Precise, Autonomous, Mechatronic — uses high-precision electric actuators to control the flex lip, restrictor bar, external and internal width adjustment and lip gap of extrusion tooling. Since introducing it about two years ago, Reifenhäuser has shipped more than 160 systems to extrusion processors. It is available with new Reifenhäuser dies and Reifenhäuser Coextrusion Adapter Pro, and can be retrofitted on existing lines in the market, independent of the manufacturer. It is available for all new flat film lines from Reifenhäuser Cast Sheet Coating, and as a component for slot dies from Reifenhäuser Extrusion Systems. Also, users of dies from third-party manufacturers can retrofit it on their equipment. However, the PAM feedblock control is only available for the Adapter Pro.

What’s new? PAM 2.0. Shown at the K show on Reifenhäuser’s new Everex flat film line, it offers more functionality than the first edition, making the film and sheet process even more automated. With PAM 2.0, the systems involved in width adjustment have been fully automated.

Benefits Simplified operation of coextrusion adapters and dies through increased automation, making processors even less dependent on highly qualified personnel and resulting in energy and raw material savings. Processors now can control all quality-critical adjustments during a product change mechatronically and save up to 80 minutes compared to a manual product change. This boosts employee safety, while ensuring precision and reproducibility, so machine lines produce less off-spec film or sheet.

Reifenhäuser Inc., Maize, Kan., 316-260-2122, www.reifenhauser.com