Cooling tanks for medical tubing enhance precision

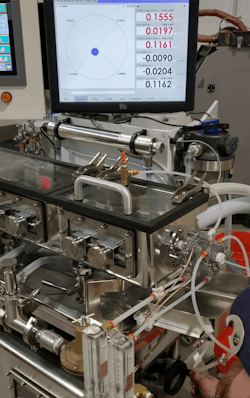

Cooling and sizing tanks Novatec has upgraded its water-cooling and vacuum-sizing tanks for medical extrusion lines. The tanks are used to process precision microbore medical tubing and are part of the company’s line of downstream equipment for medical extrusion.

What’s new? A patent-pending, water-level controlled-vacuum chamber that houses the tanks’ non-contact centering gauge. The ultrasonic gauge, which measures wall thickness, outer diameter and tube position, allows operators to very easily center the tube and prevent it from rubbing against the entry tooling in the tank, which can cause variations in wall thicknesses. The new vacuum chamber allows the gauge to be much closer to where the tubing exits the hot face of the extrusion die.

Benefits Tighter tolerances. Positioning the ultrasonic transducers only 2 to 3 inches from the die face, instead of 18 to 20 inches, allows for more precise control of the process and tighter tubing tolerances.

Novatec Inc., Baltimore, 410-789-4811, www.novatec.com