Novatec system cures, cuts TPU medical tubing

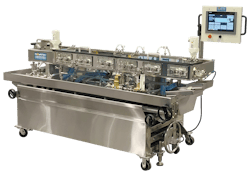

MVT series This downstream extrusion package from Novatec is designed to cool and cure TPU medical tubing, specifically single- and multi-lumen microbore tubing, and cut it to length. It also is appropriate for PVC, TPE and PE tubing. The package includes an 8-foot-long water tank with three stages that the tubing passes through: a hot zone, a cold zone and a warm zone. Each zone has its own water pump, heat exchanger, modulating valve and heater. Also included is a combination puller/cutter and an oven conveyor. The system typically operates at speeds of 20 to 50 feet per minute.

What’s new? The system, and its automated, multi-pass approach to cooling and curing hard-to-cut, tacky TPU tubes. This contrasts with traditional setups, in which the tubes are cut longer than required, manually hung on racks and allowed to cure before being cut to length manually.

Benefits Efficiency, precise cutting and space savings. The system reduces shrinkage of the tubing and minimizes tackiness via controlled cooling; this allows processors to meet the critical ovality and concentricity requirements of specialized medical tubing. Additionally, the equipment features special fittings and rounded corners to minimize the growth of biofilms.

Novatec Inc., Baltimore, 410-789-4811, www.novatec.com