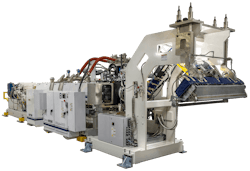

SGTSE MultiResn Processing Technologies International (PTi) originally introduced this twin-screw dryerless sheet extruder as the HVTSE (High Vacuum Twin Screw Extrusion), and is rebranding the latest version under the name Super-G Twin Screw Extruder with Multi-Resin capabilities (SGTSE MultiResn). It features fully intermeshing co-rotating, self-wiping screws, with high vacuum venting that eliminates the crystallizing and drying processes. The starve-fed system allows for blending, coloring and changeovers to be accomplished quickly, reducing downtime, maintenance and start-up times. The extruder can process a variety of virgin, post-consumer and post-industrial resins and flake, including PET, polylactic acid (PLA), PP, PS, PE and other blends.

What’s new? Newly configured square barrels with higher heater-to-barrel mass density ratios for faster heat-up. The L/D ratio has been upgraded from 52-to-1 to 50-to-1 for a smaller footprint without reducing output rates. Several components have been re-engineered for extended life and easier maintenance.

Benefits Improved energy efficiency and resource management, with up to 15 percent greater production output per horsepower. The dryerless technology saves floor space and energy, and the multi-resin capability makes the extruder versatile.

Processing Technologies International LLC, Aurora, Ill., 630-585-5800, www.ptiextruders.com

Vital Statistics

Model Throughput (pounds per hour)

|

PET |

PP |

PS |

PLA |

|

|

70mm-50D |

1,600 |

1,200 |

1,300 |

1,400 |

|

90mm-50D |

2,800 |

2,400 |

2,500 |

2,600 |

|

110mm-50D |

3,800 |

3,200 |

3,400 |

3,600 |

|

130mm-50D |

4,900 |

4,100 |

4,300 |

4,500 |

About the Author

Lynne Sherwin

Managing Editor

Managing editor Lynne Sherwin handles day-to-day operations and coordinates production of Plastics Machinery & Manufacturing’s print magazine, website and social media presence, as well as Plastics Recycling and The Journal of Blow Molding. She also writes features, including the annual machinery buying survey. She has more than 30 years of experience in daily and magazine journalism.