NPE Booth S22027

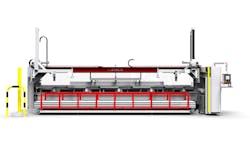

iQ Stack Exelliq’s iQ Stack system lets users automate the stacking of extruded profiles inline with the extrusion process. As a length of profile bar is cut from the extrusion strand, a roller conveyor guides it into the iQ Stack machine, where a turning unit can rotate it up to 180 degrees. A pusher moves the profile sideways onto supporting arms for intermediate storage, and this process repeats until a full layer of profiles is deposited on the supporting arms. As the supporting arms are filled, two gripper units pick up the entire layer, the supporting arms swivel out to the side and the profiles are placed in the unit’s transport rack. The gripper and supporting arms then return to their original position, repeating the process until the transport rack is filled. The system automatically feeds the transport rack, centers it, then pushes it out when it is filled. Users can manually position the gripper units to set the profile length between 14.7 feet and 21.3 feet; an optional automatic length adjustment allows for a minimum profile length of 10.2 feet.

What’s new? The iQ Stack.

Benefits Automation that integrates seamlessly into extruder lines with Exelliq’s machine control, Digi.Control. This frees up workers for other tasks and makes it easier to move finished profiles directly from the extrusion line to their final destination. Available options include automatic insertion of plastic or cardboard separating strips, length and weight measurement of each profile bar; optical quality control using a camera; and remote maintenance.

Exelliq US Meadville Inc., Meadville, Pa., 814-333-2060, www.exelliq.com

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.