Changing market demands prompt JSW to release new extruder line

By Bruce Geiselman

Japan Steel Works America (JSW) Inc. has launched a new extruder line designed to meet a growing demand by plastics processors for extruders that can be delivered quickly and at a more reasonable price, according to the company.

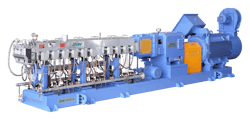

The TEX-αR (TEX- Alpha R) series of twin-screw extruders was one of the highlights of AMI Plastics World Expos North America in November in Cleveland.

“The main feature is a very short delivery time,” said JSW engineering manager Kentaro Komoda. “After four or five months, you can get a new extruder in your hands. Regarding specifications, JSW is good at the very high-end extruders — high torque, high specifications, and high durability, but our new customers’ trend is more for intermediate level. That's why we introduced the global standard model in this market.”

To facilitate fast delivery, JSW has standardized components and optimized its supply chain. The TEX-αR series is available in five sizes with screw diameters of 47 mm (TEX44αR), 58 mm (TEX54αR), 69 mm (TEX65αR), 82.5 mm (TEX77αR) and 96.5 mm (TEX90αR). All models come with wear-resistant barrels and screws and a Siemens PLC or equivalent, according to the company’s website.

The TEX-αR can be widely used for a variety of applications, including producing masterbatch or polymer alloys; polyolefin, GF (glass-filled), filler, engineering plastics or general compounding; recycling; and coloring.

JSW has standardized barrel and screw configurations for each application, and it can provide customers with an appropriate extrusion system to achieve appropriate throughput and excellent kneading performances, according to the company.

Contact:

Japan Steel Works America Inc., Farmington Hills, Mich., 248-536-0288, www.jswamerica.com

About the Author

Bruce Geiselman

Senior Staff Reporter Bruce Geiselman covers extrusion, blow molding, additive manufacturing, automation and end markets including automotive and packaging. He also writes features, including In Other Words and Problem Solved, for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He has extensive experience in daily and magazine journalism.