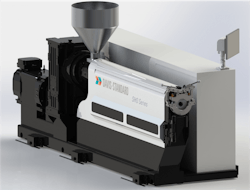

Davis-Standard kicks off energy-efficient extruder

SHO Davis-Standard’s new SHO extruder is especially suited for high-viscosity HDPE applications, such as pipe extrusion, where lower melt temperatures and energy efficiency are key. It has an L:D ratio of 42:1 and comes in barrel diameters ranging from 2 inches to 6 inches.

What’s new? The extruder, which features the company’s high-performance DSB barrier screw and an optimized, grooved feed section that builds on the company’s existing feed-section technology. The SHO also includes the company’s next-generation gearcase, along with a streamlined hopper, low-profile power panel, rugged base and fully enclosed components.

Benefits Space savings and greater output. The new gearcase and other improvements combine for a compact footprint. The extruder has outputs 20 percent greater than the company’s existing models with grooved feed sections. Additionally, it is more energy efficient, for cost savings and a reduced carbon footprint, and has reduced purging and changeover times.

Davis-Standard LLC, Pawcatuck, Conn., 860-407-6299, www.davis-standard.com