S&E Specialty Polymers, a manufacturer of standard and custom plastic compounds and concentrates, is continually enhancing its materials-handling, manufacturing and testing capabilities and developing new products to set itself apart from the competition.

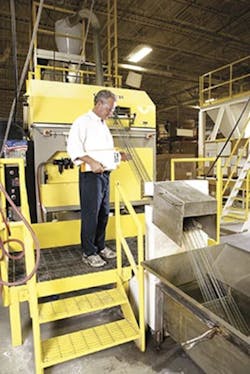

The company, located in a two-story, 60,000-square-foot building in Lunenburg, Mass., operates six compounding lines with a total of 65 million pounds of annual capacity. The machines produce polyolefin- and vinyl-based formulations, in runs ranging from 50 pounds per hour to 5,000 pounds per hour. Three of the production lines are dedicated to polyolefin production and are versatile enough to handle different screw designs to process a range of polyolefin grades, with the remaining three lines processing PVC-based recipes.

S&E has three continuous extruders, two Banbury mixing extruders and a twin-screw compounding unit at the facility; the building also houses a state-of-the-art R&D and quality-control laboratory where it evaluates a wide range of material characteristics, said Duane E. Shooltz, president and managing partner.

S&E develops and manufactures masterbatches and compounds based on thermoplastic elastomers (TPEs), thermoplastic olefins, thermoplastic rubbers and PVC. The company places an emphasis on the development of chemical formulations that impart additional qualities to the materials, such as oil- or flame-resistance, low-smoke creation, antistatic properties and weatherability, said Ilia Charlat, VP of R&D and technical sales.

It has developed thousands of custom formulations used in a wide array of end markets, including wire and cable, vehicle parts, shoes, batteries, packaging, and other consumer and industrial products.

IN-HOUSE INNOVATION

Consistent operating and manufacturing practices are vital in the efficient production of quality compounds, Charlat said. A commitment to continuous innovation is a key driver, Shooltz said.

"Not many companies our size are dedicated to reinvesting, but it is a core focus for us. We average $500,000 per annum in reinvestment," Shooltz said. That reinvestment takes the shape of upgrades to manufacturing and material storage equipment, worker training and facility expansion.

Several recent and ongoing in-house innovations reflect the company's goal to broaden and improve its product portfolio and increase capacity.

Most recently, in May, the company completed the installation of a bulk material delivery system and a new tote dumper that improves employee safety and production consistency. The system lifts a large sack of raw material to a mezzanine where the blenders and mixers are situated, then weighs and dispenses the ingredients or additives into a blender serving a specific production line. The bulk delivery system serves the company's highest-throughput line, which processes 5,000 pounds per hour.

"The technician responsible for dumping the additive into the blender of that line faced a daunting task if there were large production [runs]," Shooltz said.

The company previously purchased additives in 55-pound bags. The technician was responsible for cutting open the bag, taking it to the blender, dumping the contents manually into the blender, then stacking the bags. If the job called for processing 40,000 pounds of material, the worker would have to cut, move and dump approximately 120 sacks of additives into the 5,000-pound-capacity blender, a time-consuming and laborious task.

S&E purchased the used bulk delivery system in February from a drug company, modifying the system to its needs. The system reduced packaging and eliminated a potential bottleneck in its highest-output line. S&E also redesigned a vibrating table to pivot so that the operator can dispense exact material amounts into a different blender unit. Each production line has both a 2,500-pound-capacity blender and a 5,000-pound-capacity blender to accommodate varying throughputs.

S&E also incorporated a tote-dumping system serving another high-throughput line to speed the delivery of material to a blender. "Historically, we used a vacuum system to draw raw material from a tote into the blender. However, the vacuum system was slow and the operator was required to walk up to the blender on the mezzanine and down to the tote on the floor level to ensure the system was properly functioning," Shooltz said. The tote-dumping system lifts large bags of material weighing as much as 1,500 pounds to the blender mezzanine where the material is dispensed through a volumetric, loss-in-weight feeder.

The bulk-delivery and the tote-dumping systems handle additives that are shipped from the company's warehouse in nearby Ayer, Mass. Base resins are housed in one of a dozen 120,000-pound-capacity silos at the manufacturing plant. On-site tanks store, heat and deliver oil used to enhance the compounds' hardness. This year the company will install a new oil-delivery system that feeds directly to the compounding lines and features an on-demand heating unit. Several 60,000-gallon liquid feeder tanks deliver raw materials to the production lines.

The materials-handling equipment is just one major investment the company has made recently. One of its largest investments came in 2014, when it purchased a 53mm co-rotating twin-screw extruder, along with auxiliary equipment and several replacement screw sets, from Entek Extruders, Lebanon, Ore. According to Shooltz, the unit takes up half the space and delivers twice the throughput of the older 100mm twin-screw model it replaced. "The new line helped S&E expand its toll compounding capabilities to 15 million pounds per year. The machine allowed us to increase our product portfolio by at least 20 percent," Shooltz said.

In addition to the equipment, the company is also beefing up its software and making other plant upgrades.

It is in the midst of installing Microsoft's Dynamics GP, its first enterprise resource planning (ERP) system, which will link data on its inventory of raw materials with information on machine availability, production, maintenance and allocation of labor. Manufacturing software from BatchMaster Manufacturing, Irvine, Calif., is installed in the ERP system. Shooltz said the new system enhances the company's ability to further classify compounds by the ingredients that make up a recipe. The ERP system will allow the company to add bar-code reading capability to its operations, which will reduce product identification times.

S&E plans to install terminals connected to the ERP system at each of its manufacturing cells, where line operators can pull up details regarding the formulations they are processing. It also is working on an interface that will simplify the way its older equipment connects to the ERP. The ERP links material inventory and production with management-related tasks.

And, S&E isn't limiting its capital expenses to machinery. Last year, it installed a solar panel array atop the roof of its facility, which went active on Dec. 31. "Use of the solar array does not do a lot right now in terms of energy savings, but it helps, and it takes us in the direction of being a good corporate citizen. We expect to see more favorable returns in the long run," Shooltz said. The company says it has reduced its energy consumption.

HIGH-END LABORATORY

A mid-size company, S&E offers a wide array of testing and evaluation services.

Operators conduct a variety of tests on variables such as moisture content, tensile strength, flammability, gloss and more. Their equipment includes: an injection press with 30 tons of clamping force from Boy Machines that produces test samples; an Atlas HVUL burn chamber and other flammability-testing technology; equipment for measuring falling weight and impact; plastometers for melt-index measurement; test stands to evaluate durometer; a Mettler HR73 halogen moisture analyzer; four single-screw lab extruders, including a Boy model; a 28mm twin-screw extruder from Steer; and four testing ovens.

The physical properties of a compound are modified and tested using calibrated automated test equipment in a room that meets strict protocols for temperature and humidity testing, Shooltz said. Rooms and equipment also have been dedicated to weatherability testing, color matching and testing, low-temperature probing and the creation and testing of color concentrates, which is a new venture for the company. One lab has about a dozen pieces of equipment that test injection molding, extrusion and blow molding material formulations for automotive applications.

Overall, S&E's R&D and quality-control laboratory is set up much like the company's production space: Half of the laboratory has equipment to serve PVC formulations, while the other half of the lab is for polyolefins. "Every box of polyolefin material is subject to five basic tests — melt flow, tensile, Izod, flexural modulus and flame-resistance — while every box of PVC-based material produced is tested for hardness, gravity, density, tensile elongation and quality of extrudate," Charlat said.

MATERIAL MOTIVATIONS

The company's reject rate for its compounds is less than 1 percent. Although low reject rates are an indication of a tightly controlled process, S&E continues to strive to maximize efficiencies. Its approach to material development is founded on the challenge of creating formulations that provide more than one property and that perform better or cost less than engineering resins or rubber.

For example, Charlat spearheaded the development of two new families of compounds two years ago that are reaching the market now. "Those involved with PVC said the market was fully mature in terms of product variation and development, and that was 20 years ago," Charlat said.

S&E's new PVC compounds move away from the use of conventional liquid plasticizers with surprising results. They provide a combination of properties such as low-smoke creation, flame retardance and heat resistance, and can compete with fluorinated ethylene propylene (FEP) in harsh wire and cable applications but at the lower cost of PVC.

The PVC formulations represent a blending of different chemistries and new material attributes. "Engineering a product for low smoke, easy. Creating a formulation with low smoke and flame-resistance, easy. But combining low smoke, flame resistance and high-temperature resistance, along with a reduced halogen content, that is special and due to polymer chemistry," he said.

The new PVC compounds are not chlorinated products but are still PVC, Charlat said. The company invested 18 months of research into the product. "This is the basis of being a custom compounder, taking a base material and combining it with a range of new additive formulations to create different characteristics suitable for different applications," he said.

In addition to the new PVC family, the company has also introduced a line of chlorinated PE-based compounds (CPEs) and a family of universal TPE compounds. Also, recently, it began offering masterbatches composed of up to 85 percent active ingredients.

PRODUCTION POWER

The plant, built into the side of a hill, provides a nearly ideal flow of raw materials in, finished goods out. Incoming additives are transported by truck from the warehouse to one of three docking stations in the receiving bay. The sacks are unloaded into lanes that correspond with the production machine slated to process the material.

Ingredients for the formulation are added to the blender, then conveyed to the extruder, either a Farrel Continuous Mixer, an Entek twin-screw unit, or a Banbury mixing extruder. Many of the processing machines have been in service for years (since the 1950s for one of the Banbury machines). The finished product is packaged in a shipping container, then placed onto one of 16 lanes for shipping to the customer.

Despite the range of machine brands used, S&E maintains tight control over production by understanding the capability of each processing unit, and by standardizing auxiliary equipment. For instance, all feeders are from Coperion K-Tron, Sewell, N.J., and use Coperion's K-Vision control technology.

To improve production rates, S&E added several Gala underwater pelletizers. It also uses strand pelletizers.

ACQUISITION BINGE

S&E has 61 employees and operates in two 12-hour shifts, five days a week. The company has been on a hiring binge, adding 10 employees since the beginning of the year. According to Shooltz, company owners would like to see S&E generate annual revenues of $200 million in five years' time.

The expanded workforce seems in perfect accord with acquisitions undertaken by company owners Steven Grubman Graham and Eric Grubman. The company is named after the men, who formed it in 2005. It's part of the Toner Plastics Inc. group of companies owned by Graham. Toner Plastics, East Longmeadow, Mass., is an extruder and injection molder that Graham and his wife, Jean, founded in 1989. The group's companies also include: Modern Mold & Tool Inc., a Pittsfield, Mass., custom injection molder and mold maker; and the Beadery, a Hope Valley, R.I., maker of injection molded beads. In May, Steven Graham acquired Streamline Plastics Co. Inc., Bronx, New York, an injection molder and extruder.

Mikell Knights, senior staff reporter

Just the factsCOMPANY: S&E Specialty Polymers LLCHEADQUARTERS: Lunenburg, Mass.OWNERS: Steven Grubman Graham, Eric GrubmanFOUNDED: 2005EMPLOYEES: 61ANNUAL SALES: Not disclosed