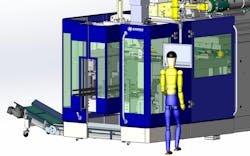

KEB Grey Kautex is relaunching its KEB series of extrusion blow molding machines, which debuted in 1968. The new version, dubbed KEB Grey, is designed to create technical hollow parts and complex packaging, such as multilayer containers and jerry cans with integrated handles. It has a flexible clamping unit with tie-bar-less scissor design for easy tool changes; adjustable architecture to accommodate processes such as multilayer extrusion, angled neck calibration, integrated cooling stations and bottom blow; and an ergonomic layout with enhanced accessibility and a process-focused operation station with a 24-inch smart HMI interface.

What’s new? The KEB Grey line.

Benefits Flexibility and energy efficiency in a compact package with minimum maintenance requirements. The KEB Grey line can be configured for post-consumer recyclate (PCR), rapid cooling masks or complex post-processing, and is backward-compatible with existing KEB molds and die heads.

Kautex Machines Inc., Flemington, N.J., 908-512-7664, www.kautex-group.com

About the Author

Lynne Sherwin

Managing Editor

Managing editor Lynne Sherwin handles day-to-day operations and coordinates production of Plastics Machinery & Manufacturing’s print magazine, website and social media presence, as well as Plastics Recycling and The Journal of Blow Molding. She also writes features, including the annual machinery buying survey. She has more than 30 years of experience in daily and magazine journalism.