Fundamentals of polyolefin structure-property relationships in blow molding applications

By Hyunwoo Kim and Saurav S. Sengupta

Dow Packaging & Specialty Plastics

Blow molding is one of the most widely used processes to manufacture rigid packaging for food, household industrial chemicals, personal-care, agricultural chemicals and pharmaceutical products.

A modern blow molding process was derived from glass blowing and nowadays, a wide range of thermoplastic resins are used for blow molded bottles including polyolefins (PE, PP, PVC, PC and PET). Among these, PE is the predominant material for blow-molded containers due to its favorable rheological behavior during melt processing and its well-balanced mechanical and chemical resistance properties.

The most important characteristic that defines PE is that it melts under relatively moderate temperatures with desirable solid-state properties at room temperature. Thanks to excellent heat stability, this process can be repeated to allow the reprocessing or recycling of PE with a minimum shift in physical properties.

PE resins are also very flexible, durable and chemically inert, making them an ideal choice for containers for even highly aggressive chemicals. PE is semi-crystalline, and the size of the crystalline and amorphous region strongly influences physical properties, such as stiffness, gas barrier and hardness, of molded articles. A broad family of products can be made possible for PE by controlling these variations in structural parameters and solid-state morphology.

Catalysts, monomers and modifiers, along with polymerization reactors and reaction conditions, influence the molecular structure, molecular weight and composition of PE. Ethylene, the primary monomer, is predominantly produced from fossil-based feedstocks such as crude oil and natural gas. However, it can also be sourced from renewable bio-based feedstocks, including sugarcane, agricultural residues and waste-derived oils like used cooking oil.

Most blow molding grade HDPE resins are typically produced via a slurry- or gas-phase process. In a typical slurry-phase reactor, polymerization is performed in a liquid medium (diluent). In a gas-phase process (e.g. Dow UNIPOL™ PE Process, Innovene, Spherilene, etc.), polymerization takes place without a solvent for excellent product consistency and taste and odor performance for direct food-contact packaging applications.

Catalyst molecules (small metallic or non-metallic) that help reduce the activation energy for any chemical reaction have been at the center of innovation in polymerization. Catalysts play a vital role in the commercial-scale production of PE resins. They react with ethylene to form an intermediate, then ethylene molecules can be added sequentially to grow to longer PE molecules.

When only ethylene is present for polymerization, the final product is a homopolymer. Industry utilizes other alpha olefins such as 1-butene, 1-hexene and 1-octene for the production of PE. These co-monomers can be inserted into the growing PE chains to form short chain branches. The amount of short chain branching is an important factor that determines physical properties of the PE resins such as density, stiffness, environmental stress crack resistance (ESCR), impact strength and hardness.

PE resins, having relatively broader molecular weight distribution (MWD), are used for improved melt processability for blow molding applications. Chromium-based catalysts are most commonly used for such a broad MWD product.

There are other types of catalysts used by the PE industry, including Ziegler-Natta and single-site catalysts. They tend to produce PE resins with narrower MWD for high compositional uniformity and improved physical properties. They are less commonly utilized for the manufacture of PE resins for blow molding.

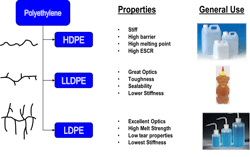

PE resins can be grouped into three main categories: HDPE, LLDPE and LDPE. The use of these resins varies globally, but generally HDPE and LLDPE are consumed more heavily than LDPE. Roughly 12 percent of the global production of PE resins goes toward blow molding applications.

When HDPE resin is produced, either no alpha-olefin comonomer or only a minimal amount is incorporated. The resulting PE chains are highly linear with limited or no side branching. When cooled from the amorphous melt state, highly mobile linear PE chains can be reorganized into ordered and denser regions referred to as crystals or crystalline domains.

LLDPE resins have a higher degree of short chain branches, which disrupt chain regularity and interfere with crystallization. The resulting solid structure has comparatively less crystallinity, resulting in lower melting temperature, density and stiffness but higher ESCR and impact resistance.

LDPE resin is a PE with a highly random chain structure often characterized by a high degree of long chain branching or “branch-over-branch” structure. LDPE resins can be less stiff and lack good gas barrier properties but can be an ideal choice for blow molded squeeze bottles that require a softer or more flexible material.

HDPE, LLDPE and LDPE resins are used for different blow molded bottle applications. Figure 1 illustrates key properties expected from these different PE resins and their typical end-use blow molded bottle applications.

Figure 1. Three groups of PE resins used in blow molding applications, their key performance properties and end-use applications

One of the latest technological advancements in the PE industry is a multimodal PE, which offers molecular architecture for design flexibility and improved property balance. A multi-reactor technology (e.g. Dow UNIPOL™ II Process, Spherilene C etc.) can produce PE resins with bimodal molecular weight distribution where a low molecular weight fraction designed for maximized crystallinity or stiffness is combined with a high molecular weight fraction designed for maximized co-monomer incorporation or improved toughness, ESCR and post-die melt processability (i.e. parison die swell and melt strength).

Multimodal PE resins such as Dow CONTINUUM™ Bimodal High Density Polyethylene products can help advance the blow molding industry’s sustainability goals. Bimodal resins can be designed for higher density while offering excellent ESCR and bottle-drop impact performance. Bottles can also be produced for lighter weight with no compromised physical properties with a bimodal PE. Bimodal HDPE resins can also help incorporate more post-consumer recycled (PCR) HDPE resins in blow molded bottles, even for high ESCR applications.

A number of physical properties for PE resins are important for blow molded bottle applications. Most of these properties can be found on the material datasheet offered by suppliers. Table 1 shows a list of physical properties of a typical PE resin. This table also lists how these properties are relevant to bottle performance, and their importance to the application.

Table 1. Typical resin properties reported on PE material datasheets

|

Property |

Definition |

Test method |

Relevance to blow molded bottle applications |

|

Density |

Weight per unit volume |

ASTM D792 Gradient Tube Method |

Part weight and stiffness, hardness, abrasion resistance and shrinkage. Bottle top load performance. |

|

Melt flow |

Mass of polymer through a capillary at a prescribed pressure at a prescribed temperature |

ASTM D1238 A “melt indexer” test |

Melt viscosity, molecular weight and molecular weight distribution. Melt processability (extruder output, power requirement and melt temperature). Part impact strength and environmental stress cracking resistance (ESCR). |

|

Flexural modulus |

Stiffness, resistance to bending |

ASTM D790 Ratio of stress to strain in flexural deformation |

Proportional to resin density. Part stiffness and bottle top load compression strength. |

|

Tensile properties |

Determined from load versus displacement when a specimen is pulled apart at a prescribed extension rate |

ASTM D638 |

Part stiffness under tensile stress. Maximum stress and strain that a part can withstand under tensile stress before permanent deformation or breaking. |

|

Tensile impact |

Amount of force needed to break a specimen under a high-speed tensile load |

ASTM D1822 A pendulum is allowed to strike the anvil, breaking the specimen. Impact energy is calculated from the tensile impact energy recorded. |

Low-temperature impact strength and material toughness. . |

|

Brittleness test |

Lowest temperature at which materials do not exhibit brittle failure |

ASTM D746 Temperature at which 50 percent of specimens fail by striking edges. |

Temperature at which blow molded bottle starts exhibiting brittle failure. |

|

Thermal properties |

Melting and crystallization temperature, amount of heat needed to melt or recrystallize plastic |

Differential scanning calorimetry |

Temperature where material will start to melt and where melt starts to re-crystalize. Amount of PE that is crystalline. |

|

Deflection temperature under load |

Temperature at which a plastic sample deforms under a specific load |

ASTM D648 Load applied to rectangular bar. Measures the temperature at 0.25mm deformation. |

Higher values equal higher part temperature performance and higher upper use temperature range. |

|

Vicat softening temperature |

Temperature at which a plastic sample softens, allowing indentation under stress. |

ASTM D1525 Load applied to flat specimen with an indentor. Measures the temperature at 1mm indentation. |

Higher values equal higher part temperature performance and high upper use temperature range. |

|

ESCR |

Slow crack growth of stressed polymers in the presence of surface-active substances. |

ASTM D1693 Bent specimen in a holding clamp placed in an agent at a constant temperature. The number of hours after which 50 percent of the specimens exhibit stress cracks. |

Important property that determines the suitability of material for blow molded bottles for household industrial chemicals and other stress crack agents. |

In blow molding, most material properties are interdependent. Among these, density and melt index are the primary predictors for other physical properties. For example, when higher-density PE resin is used, improved rigidity from the bottles can be expected, but ESCR and impact strength can be compromised. Higher–melt-index PE resins would offer improved flow in melt state and higher extrusion output, but other solid-state properties, including ESCR, impact strength and melt strength, can be maximized when lower-melt-index resins are used. Figure 2 illustrates the interplay of these physical properties as a function of density and melt index.

Figure 2. Influence of density and melt index in physical properties of PE resins in blow molding application

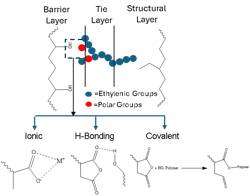

Blow molded bottles can be manufactured using multilayer construction through co-extrusion processes, enabling the integration of distinct polymer layers with tailored barrier, mechanical or aesthetic properties. For example, barrier plastics like ethylene vinyl alcohol (EVOH) or polyamide (PA) can be combined with a PE resin in a multilayer structure for the food, pharmaceutical, agricultural-chemical packaging and gasoline-container applications needing good chemical or gaseous barrier properties.

However, most unmodified PE resins and barrier plastics are incompatible due to differences in polarity and chemical nature, and form very poor bonds between the layers in a multilayer structure. Layers can separate easily, impacting the structural integrity of the bottles. To prevent the layer delamination, a third material that has both non-polar and polar characters can be incorporated in the multilayer bottles that can promote good layer adhesion to both PE and barrier plastics. These “surfactant” type of resins are called an adhesive or a tie resin in the PE industry.

Figure 3: Schematic showing adhesion in multilayered structures

Depending on the types of plastics that need to be combined in multilayer bottles, a number of compatibilization chemistries are available. The polar groups of these molecules can interact with the functional layers with ionic bonds, covalent bonds or even hydrogen bonds (Figure 3). The most common tie layer resin is PE modified with a polar functional group such as anhydride (Dow BYNEL™ Adhesive Resin). Functional groups like maleic anhydride can be grafted onto the PE resin. This ester/anhydride group can be drawn into the polar polymers like EVOH and PA, forming strong covalent or hydrogen bonding with them. The backbone of the tie molecules is still PE and can have a strong interaction with the other PE layers.

Ionomers are popular functional polymers and promote very strong electrostatic interaction with reacting groups. Dow SURLYN™ Ionomer is an example of such a molecule and is produced by neutralizing PE acid copolymers with metal salts. Typical applications of such resins result in very strong physical properties, such as excellent abrasion resistance and toughness.

The unique optical properties of SURLYN™ Ionomers can be leveraged in blow molded bottles by applying them as a skin layer, delivering enhanced gloss and scratch resistance. These attributes are particularly advantageous for personal care and cosmetic packaging where visual appeal is critical. These ionomers offer a unique balance of optical clarity and mechanical durability, not typically achievable with conventional PE, while maintaining excellent processability in blow molding applications.

PE blow molding is a foundational process in packaging that continues to evolve through innovations in resin design and processing. Core properties such as density and melt index remain central to predicting performance. HDPE’s linear structure and crystallinity enable strong, lightweight containers with excellent processability. Multimodal PE resins offer enhanced design flexibility by combining low molecular weight fractions for stiffness with high molecular weight fractions for toughness and ESCR. These resins, such as Dow’s CONTINUUM™ Bimodal High Density Polyethylene resins, further enhance design flexibility by combining stiffness, toughness and processability. These bimodal resins also support lightweighting and greater use of recycled content, aligning with the industry's sustainability goals.

Additionally, advances in multilayer co-extrusion, material engineering and the incorporation of specialty polymers, such as Dow’s BYNEL™ Adhesive Resins and SURLYN™ Ionomers, continue to expand the functional and aesthetic capabilities of blow molded containers. As sustainability and performance demands evolve, a deep understanding of PE resin behavior and processing fundamentals will remain essential for innovation in blow molding technologies.

This article appears in the summer 2025 issue of The Journal of Blow Molding.

© 2025, Society of Plastics Engineers Blow Molding Division

About the Author

Hyunwoo Kim

Hyunwoo Kim is a Senior Technical Service and Development Scientist in Dow Packaging and Specialty Plastics business. In this role, he is responsible for leading application development efforts in the Rigid Packaging market segment with focus on the blow molding technology. Hyunwoo joined the Dow Chemical Company in Core Research & Development in 2010. He received a B.S. in Chemical Engineering from Seoul National University in 2004 and a Ph.D. in Chemical Engineering from University of Minnesota in 2009. Hyunwoo is an elected board member of SPE Blow Molding Division. He holds 7 U.S. patent applications and has authored 80 Dow internal publications and 29 external publications.

Saurav S. Sengupta

Saurav S. Sengupta is a R&D/TS&D Fellow in Packaging & Specialty Plastics at Dow, where he focuses on new product innovation and process development for formulated polymer compositions. Saurav joined Dow in 2007 and led key polymer product development projects leading to R&D 100 award in 2015. He has held several leadership positions in Dow business and corporate R&D divisions. Saurav serves on the advisory council for Dow Asian Diversity Network (local chapter). He is also a board member of SPE Extrusion Division and SPE’s Diversity, Equity, & Inclusion Advisory Board. Saurav has over 23 granted patents, 38 peer reviewed publications and presentations, 1 invited article and 3 book chapters. He earned his doctorate degree in Chemical Engineering from Queen’s University, Canada, and master’s degree in Industrial Chemistry from Indian Institute of Technology, India. Saurav also holds an Executive Certificate in Global Leadership from Thunderbird School of Global Management.