By Scott Steele

In the early 1970s, when Dan Weissmann began his career in plastic packaging, very few beverages were packaged in the now-ubiquitous PET bottle. He played key roles during the evolution of plastic beverage containers and has seen the industry grow to supply billions of containers on every continent.

Weissmann was born in Israel and attended the Technion – Israel Institute of Technology, in his hometown of Haifa. His college years were interrupted in 1967 when he was called up as a reservist for the Six-Day War. At Stevens Institute of Technology in Hoboken, N.J., he earned a master's degree in mechanical engineering. Being interested in plastics, he went on to earn a Ph.D. degree in polymer mechanics.

Weissmann was the first person to create an interdisciplinary program combining the mechanical engineering, metallurgy and chemical engineering departments. Now it was time to begin his 50-plus-year career in the plastics industry, focused primarily on packaging.

After a short stint at PPG, he joined Monsanto and went to work on the Cycle-Safe Program. Cycle Safe was the trade name for Monsanto’s development of a plastic carbonated soft-drink beverage container. He was drawn to Monsanto by his mentor and lifelong friend, Mike Gigliotti, who also graduated from Stevens, although many years earlier.

In those early days, Monsanto and other companies were experimenting with acrylonitrile/styrene (ANS) for use in carbonated soft-drink bottles. Having superior gas-barrier properties, it was the only plastic material then deemed capable of achieving the long shelf life that glass and metal packaging provided. Monsanto built capacity and launched a 32-ounce bottle, dubbed the Easy Goer, the first-ever plastic carbonated beverage container to enter the market.

Weissmann also saw the genesis of packaging material recycling as a result of his work on acrylonitrile, which Monsanto saw as a necessary component of Cycle-Safe by addressing end-of-life issues. Plastics needed to compete with returnable glass and metal packaging, both of which were being recycled.

Pivoting to PET

In an ironic twist of fate, the U.S. Food and Drug Administration forced companies to quit using acrylonitrile for beverage packaging due to concerns about monomer migration reported by Monsanto’s own scientists. All production quickly stopped. But Monsanto’s loss was the PET industry’s gain as Weissmann, and many of his colleagues, went to work for the companies that continued the pursuit of a plastic beverage container — and brought along their Cycle-Safe experience.

The Pepsi-Cola and Coca-Cola brands had seen the potential for plastic, and the PET bottle race was on. Weissmann went to work for Continental Can Co. The first priority was production startup at the Pine Brook, N.J., manufacturing plant. Continental pioneered the one-piece beverage container. Competitors were making two-piece containers with injection molded, glued-on base cups. However, the economics of the one-piece bottle were superior and one-piece technology eventually won out.

In the early Pine Brook days, quality control tools were limited and the machines lacked process stability. Some quick methods to check material distribution were needed. Section weight monitoring became the main indicator for material distribution. Weissmann and his team invented a hot-wire bottle sectioning cutter, which became the world-standard tool in quality control of PET container production.

Weissmann has run across many acquaintances who are in the “who’s who” in the plastics industry. One of the co-ops in the Pine Brook plant was accounting intern Bill Long, who went on to become president of Amcor Rigid Packaging. Amcor became the biggest packaging company in the world.

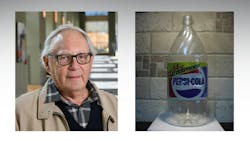

Weissmann’s home office in Simsbury, Conn., is a museum of firsts from the beverage industry. He has saved an early Pepsi Swirl bottle produced at Pine Brook. It is an early example of how PET could be used to create decorative shapes, which now is the norm for packaging.

Teaching and consulting

Weissmann left Continental for personal reasons and spent several years in a sheet extrusion plant. At the same time, he volunteered to teach at Central Connecticut State University’s (CCSU) plastics technology program. This had been set up in partnership with SPE’s Connecticut section. He taught several classes there, including a lab.

He contributed to another major development — a plastic closure for hot-fill packaging. This work with White Cap Closures led to development of the VHS 43mm finish, which became the industry standard. Hot-fill production started at an operation in Cincinnati.

Weissmann recalls the success of the package which, as he describes it, “knocked the glass off the shelves.” The transition was fast: “The glass bottle weighed almost as much as the contents. Since the brand was selling to kids, the lightweight plastic bottle was a hit,” he said.

Monsanto eventually sold its beverage operation to Johnson Controls Inc. (JCI, which later became Amcor), but Weissmann stayed on at Monsanto, rejoining the PET bottle business at JCI in 1994. In 1998, he joined a development organization associated with University of Massachusetts Lowell (UMass), the goal of which was trying to commercialize a technology based on compression molding PET disks into preforms and bottles. The process had been invented by Emery Valyi, who donated the patents to UMass. The process didn’t pan out and Weissmann once again began consulting, including an extended stint at Amcor.

In 2008, while semi-retired, he began writing articles for a packaging magazine, which number more than 140 at last count. His articles cover conferences and trade shows, new technologies and some of the history of blow molding and packaging. If you have attended SPE’s Annual Blow Molding Conference (ABC), you likely have heard him asking tough questions of the speakers due to his insatiable desire to learn and explore strategies for the future.

Weissmann was program chairman for the 1993 ABC, held in New Jersey, when he was on the Blow Molding Division’s board of directors. He has remained a supporter of the division for many years.

In addition to being inquisitive, he values learning and hence teaching both professionally and as a volunteer. While teaching at CCSU he composed the technical outline for Paulson Training’s blow molding program (based on VCR tapes!). He also conducts internal training for his many customers.

Weissmann has lived in Simsbury, Conn., since 1973. His wife, Nancy, grew up in Newark, N.J., but spent time in Israel. In fact, Weissmann met his wife of nearly 60 years while they both were working at a kibbutz in Israel growing cotton. They occasionally travel back to Israel where Weissmann still has a brother.

They have two adult children, son Michael and daughter Galit, and two grandchildren. During Michael’s college years, he was fortunate to receive a scholarship from the Connecticut SPE section.

This article appears in the summer 2025 issue of The Journal of Blow Molding.

© 2025, Society of Plastics Engineers Blow Molding Division

About the Author

Scott Steele

Scott Steele is the owner of SWS Consulting LLC in Perrysburg, Ohio. An expert in reheat stretch blow molding, he has been a member of the Society of Plastics Engineers for more than 30 years and has held positions as chairman and director of the Blow Molding Division. Contact him at [email protected].