By Ron Shinn

German blow molding machinery manufacturer BBM Maschinenbau und Vertriebs GmbH is building a sales and service organization in the U.S. for its electric and hybrid extrusion blow molding machines.

Industry veteran Andrew Hobson is Director of Sales for BBM America.

BBM has about 30 blow molding machines in operation in North America, primarily in shops that have European parent companies that are familiar with BBM in Europe.

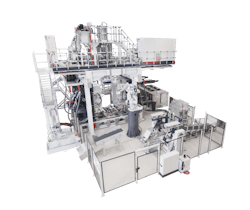

The company’s machine portfolio includes electric single-station and double-station EBM machines for packaging; electric single-station and double-station jerrycan machines for containers 5 liters to 40 liters; compact single-station machines for stackable containers up to 20 liters; single-station and double-station electric EBM machines for drums and technical parts; large hybrid machines with up to 650 tons of clamping force for technical parts and tanks up to 5,500 liters; and electric suction blow molding machines.

BBM also builds three-layer accumulator heads.

Hobson said the BBM accumulator heads on machines up to 180 tons of clamping force are all electric. Larger machines are hybrids with electric platen movements and hydraulic clamp-up units.

The BBM electric machines feature low maintenance costs since they do not use oil or filters and do not need energy for cooling the hydraulics.

BBM also sells complete work cells with all auxiliary equipment required for an application. Options include automation with robot takeout; post-processing; punching unit; post cooling; multi-cavity, multi-layer electric or hydraulic partial wall thickness distribution (PWDS); and electric die centering. Compact electric blow molding machines can be configured for single, double or quadruple operation.

The company says its electric EBM machines use 50 percent less energy than hydraulic machines, have lower maintenance costs and provide easy access to production and maintenance areas. Controllers use a multi-touch screen and include remote control.

Hobson is based in Mason City, Iowa, where BBM has also established a warehouse for parts and service.

“This is our first step in this market,” Hobson said.

BBM was formed in 1998 and built its first blow molding machine in 1999. The focus has been on electric machines since 2003.

BBM’s original business was repairing, rebuilding and upgrading other brands. That business continues and it still has a massive inventory of spare parts for other brands, Hobson said. Plans are to move some of its parts inventory from Germany to Mason City.

BBM, based in Langenberg, Germany, builds 40 to 50 blow molding machines a year, Hobson said.

Contact:

BBM America, Mason City, Iowa, 319-883-9264, www.bbm-america.com

About the Author

Ron Shinn

Editor

Editor Ron Shinn is a co-founder of Plastics Machinery & Manufacturing and has been covering the plastics industry for more than 35 years. He leads the editorial team, directs coverage and sets the editorial calendar. He also writes features, including the Talking Points column and On the Factory Floor, and covers recycling and sustainability for PMM and Plastics Recycling.