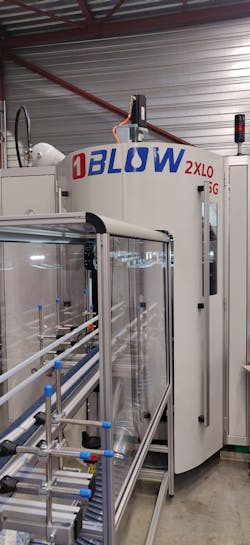

1Blow machine offers energy-efficient production

2XL 1Blow’s latest blow molding machine has two cavities and can make PET bottles with a maximum capacity of 12 liters, a maximum height of 16.1 inches and a maximum diameter of 8.9 inches. Its output ranges from 1,400 10-liter bottles per hour to 3,400 half-liter bottles per hour. The 2XL’s motions are 85 percent rotary and only 15 percent linear for smooth, energy-efficient production. Options include neck orientation and the ability to make hot-fill and oval bottles.

What’s new? The 2XL, which hit the market in the fourth quarter of 2020. Also new is the option to incorporate the company’s recently introduced Sure Grip technology for creating bottles with handles. Because the handle is directly molded into the bottle, no additional plastic parts are required, making the bottle 100 percent recyclable.

Benefits Speed, efficiency and economy. The all-electric, compact machine has a small footprint, is engineered with fewer wear parts and has optimized movements, leading to low operating costs. Additionally, product changeovers can be completed in 90 minutes or less.

1Blow, Atlanta, 678-865-2665, www.1blow.com