Patent Report: Nissei molding process handles 2 liquids

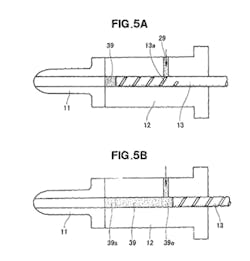

Nissei Plastic Industrial Co. Ltd. has been awarded a patent for an injection molding machine capable of handling two liquids for producing parts made of materials such as liquid silicone rubber (LSR). The machine was previously patented in Japan, where Nagano-based Nissei is headquartered.

According to the patent, the machine has a liquid supply passage within its mixing block that supplies the liquids separately. The machine's injection cylinder supports the mixing cylinder, and the machine's screw mixes the components. Once mixed, the liquid enters the injection cylinder. To protect against the materials solidifying, heaters maintain the temperature in the injection cylinder and mixing cylinder.

Patent 9,931,774; issued April 3

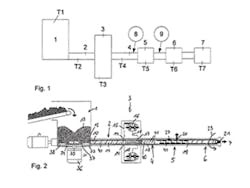

Plastic granule production. Maag Automatik GmbH, Grossostheim, Germany, has been granted a patent for a device to make granules from a plastic melt. Designed for materials such as glass-fiber-reinforced polyamide, the strand-granulating system can create strands of melt that do not clump or break. It first melts the material, then discharges it in multiple strands from a perforated plate. After they cool, the strands can be cut into pellets.

According to the patent, the system addresses concerns with other technologies that can damage strands of material as they are discharged. To prevent this, the technology uses a high-temperature impinging medium, such as heated air or an inert gas, which removes clumps.

"The higher temperature of the impinging [medium] alone helps to prevent clumping and deposition of the melt material near the perforated plate and also helps to remove deposits that build up near the perforated plate in an especially efficient manner," the patent states.

The patent also states that the technology was used at Maag's technical center, where the company produced fiber-reinforced material using a 100mm slot nozzle with a 0.5mm gap height to release the impinging fluid.

Patent 9,808,979; issued Nov. 7

Recycling. Erema Engineering Recycling Maschinen und Anlagen GmbH of Ansfelden, Austria, has patented a method for recycling plastics that involves multiple steps. The plastic is pulverized, melted, filtered to remove impurities, homogenized, degassed and reprocessed.

The purpose of the invention is to provide an improved, highly productive process for recycling plastics that delivers a high-quality final product.

The system includes at least one unit to perform each of the following steps: reprocessing, heating, filtering, homogenizing and degassing, with a final machine devoted to the processing of degassed melt. The units are connected to each other in order of the steps.

Compared to the previously existing methods, contaminants and gas bubbles are fewer, smaller and more evenly distributed in the final product, improving quality.

Patent 9,808,963; issued Nov. 7

3-D printing. X Development LLC, a Mountain View, Calif., company that describes its mission as making moonshot technologies, has received a patent for a 3-D printer that uses a multitude of light sources to cure photoreactive resin. By employing multiple light sources, or rods, the printer could print more rapidly than current technologies. According to the patent, the rods extend into the resin, creating hollow, honeycomb-type shapes, reducing the amount of material that would be needed to make a part with traditional printers. Some iterations of the printer could include a robotic arm to suspend a base plate above the resin container.

"The control system may then operate one or more ultraviolet (UV) light sources to emit radiation into their corresponding rods," the patent states. "The UV radiation from each source passes through each corresponding rod and into the surrounding resin, which cures the surrounding resin to form a voxel around the rod."

Patent 9,840,045; issued Dec. 12

Patents and patent applications can be viewed at www.uspto.gov

Have you applied for or received a patent? Contact [email protected]