Rhode Island-based US Extruders is putting an emphasis on operator safety, company President Bill Kramer said. The new machinery manufacturer is touting some novel safety features, while other extruder makers, including Leistritz Extrusion and Dual Spiral Systems, noted a continued trend among users to employ insulation shrouds to prevent operator injury.

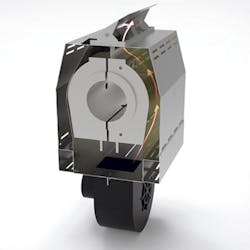

US Extruders manufactures single-screw extruders with screw diameters ranging from 1 inch to 8 inches. The company began selling the machines in September.

The machines feature standard safety devices, including an emergency-stop button near the feed opening, a rupture disc, which is a pressure-relieving device at the barrel discharge, and the typical guarding.

However, US Extruders also employs some unusual safety features, Kramer said, such as an automatic adjusting motor base to maintain belt tension.

"I think we are the only ones using a pivot base that provides automatic tensioning," Kramer said. "This kind of a pivot base is used in the big fan industry on things like a fan in your roof because that is a place where you wouldn't want to send maintenance people to adjust a fan belt."

Typically, on smaller and medium-size extruders, the belt that is connected to the motor requires manual adjustments. Maintenance workers need to remove a guard and adjust screws to control the belt tension. However, sometimes workers fail to replace the guard or if mechanics are unavailable, operators might attempt to make the adjustment themselves, which can create unsafe conditions, Kramer said. By automatically adjusting belt tension, US Extruders eliminates those concerns.

To keep the outer surface of the extruders cool, US Extruders heater shrouds are double-walled with an air gap between the inner and outer surfaces; ventilation slots provide convective airflow between the two walls. This enhances safety by reducing the chances of a worker being burned from touching a hot surface, Kramer said.

Also, the company's extruders feature a barrel clamp that links the upper and lower halves of the C-clamp so that they counterbalance and open and close together. The design prevents an operator from dropping the heavy upper clamp onto his or her hand. This feature is particularly beneficial in custom profile operations where operators may need to change dies several times per day.

Workers typically need to open the C-clamp whenever changing dies, cleaning die heads or changing screens in breaker plates.

"A profile house may change dies a couple of times per day because they run short runs of some special profile, and then they set up and run something else," Kramer said. "They may be opening that [clamp] often. We have a unique design that links the upper and lower halves together. When you raise the upper, the lower comes down. They are counterbalanced, so it eliminates the possibility of them falling under their own weight."

The design is unique to US Extruders, Kramer said.

Leistritz Extrusion reports a recent trend among customers is to equip twin-screw extruder barrels with insulation in addition to the barrel cover insulation. The optional additional insulation protects workers from burns.

"By having two layers of insulation and an air gap between the barrel and the barrel cover, there's a much larger difference in temperature," said Charlie Martin, Leistritz Extrusion president and GM. "In addition to preventing burns, this insulation design saves a significant amount of energy."

The optional additional insulation typically wraps around a large part of the barrel.

"The insulation wraps around and is affixed with straps," Martin said. "The insulation dimensions, openings and folds are customized to each barrel."

Dual Spiral System began adding shroud insulation to its extruders last year to reduce the possibility of burns by operators who are servicing extrusion lines. The insulation provides a better thermal barrier, company President Rafael Castillo said.

"This is particularly important for coex lines that have many extruders crowded around the extrusion die," Castillo said.

The insulation also saves energy, Castillo said.

Bruce Geiselman, senior staff reporter

For more information

Dual Spiral Systems Inc.,Burlington, Ontario, 905-524-2438, www.dualspiralsystems.com

Leistritz Extrusion,Somerville, N.J., 908-685-2333, www.leistritz.com/en

US Extruders,Westerly, R.I., 401-584-4710, www.us-extruders.com

About the Author

Bruce Geiselman

Senior Staff Reporter Bruce Geiselman covers extrusion, blow molding, additive manufacturing, automation and end markets including automotive and packaging. He also writes features, including In Other Words and Problem Solved, for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He has extensive experience in daily and magazine journalism.